LiDAR cover glass

- LiDAR Components and Principles

- High infrared transmittance

- Protection (impact resistance)

- Corrosion resistance

- Heat resistance

- Specialty glass

- IR transmitting cover glass (Black type)

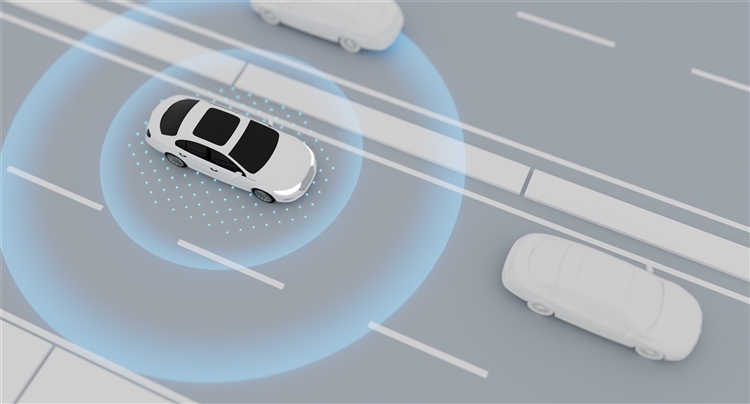

01/What is LiDAR?

LiDAR, an acronym of “Light Detection and Ranging”, is a technology used to measure distances using laser light. The positions of objects are detected by emitting a laser beam at them and detecting the reflected light in return.

LiDAR, an acronym of “Light Detection and Ranging”, is a technology used to measure distances using laser light. The positions of objects are detected by emitting a laser beam at them and detecting the reflected light in return.

Range finding methods include ToF (Time of Flight), or triangulation. LiDAR mainly uses the ToF method, but starting from around 2019, the use of the FMCW (Frequency Modulated Continuous Wave) method has increased.

LiDAR is already used in a wide variety of fields. Examples include construction, topographical surveying, and even robot vacuum cleaners. In recent years, the technology has even been used in consumer devices such as the following for 3D mapping and measuring of local environments.

- Automated vehicle operation (ADAS/Autonomous driving)

- AR/VR devices

- Smartphones

LiDAR is able to measure distances more accurately than conventional distance measurement sensors, and it is anticipated that the technology will be employed to be the “eyes” of machines going forward.

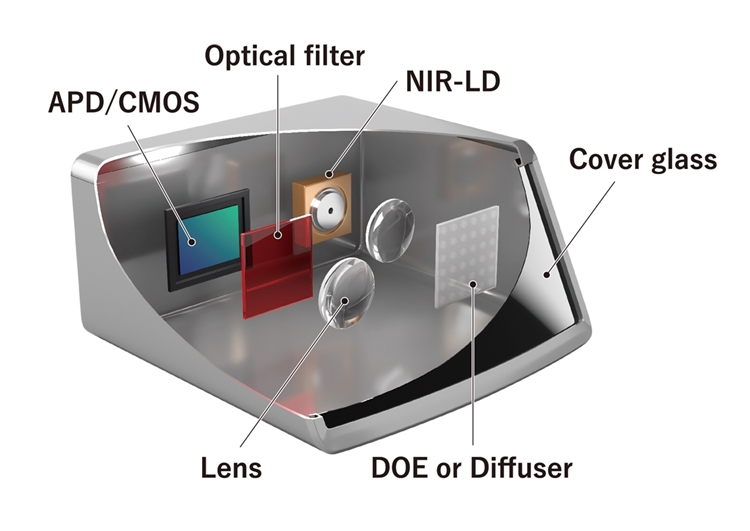

LiDAR Components and Principles

The two major components of LiDAR are the emitter, which emits the laser beam, and the receiver, which detects the reflected light.

The emitter uses a NIR-LD (near-infrared laser diode), and the receiver uses an APD (Avalanche Photodiode) / CMOS (Image sensor).

In order to control the emitted laser beam and receive the reflected light accurately, the following optical components are required between the emitter and receiver.

- Lenses

- Diffractive optical elements or diffusers

- Cover glass

- Optical filters

In LiDAR systems, lenses that best suit the application are used to control the projected laser beams, and diffractive optical elements or diffusers are used to expand the target area of the emitted light. Lenses focus the reflected light and optical filters remove noise. Cover glass is used to protect the internal optical components.

In order for LiDAR to generate a 3D map, a mechanism for scanning a wide area of space is required. Beam irradiation methods include a “scanning” type, in which beams are emitted in such a way to be tracing space, and a “non-scanning” type, in which beams are emitted over a wide area instantaneously.

It is necessary to choose the system that is best suited for the area to be measured and the purpose of the application.

02/The role of cover glass for LiDAR

Cover glass is used in the housing of the LiDAR. The purpose of this cover glass is to provide protection for the optical components used by the emitter and the receiver.

Cover glass is used in the housing of the LiDAR. The purpose of this cover glass is to provide protection for the optical components used by the emitter and the receiver.

Let’s take a look at the role of LiDAR specifically for automotive applications as an example.

In order for automated driving to be possible for vehicles, LiDAR must constantly scan its surroundings to detect the positions of pedestrians, obstacles and other vehicles in real-time, and with a high level of accuracy. If installed on the exterior of the vehicle, it must also be sturdy enough to withstand harsh environmental conditions and flying debris.

Consequently, cover glass must serve the purpose of protecting both the emitter and receiver from the external environment without causing attenuation or shading of the near-infrared laser light of the LiDAR.

03/Required properties of cover glass for LiDAR

In order to protect the internal optical components of the LiDAR while maintaining detection accuracy, the cover glass must have the following properties.

- High infrared transmittance

- Transparency

- Protection (impact resistance)

- Corrosion resistance

- Heat resistance

These properties, as well as the reasons why they are required will be explained in detail.

High infrared transmittance

Infrared transmittance is the ratio of the intensity of infrared rays incident on an object to the intensity of the rays that pass through it. For example, if the infrared transmittance of an object is 50%, the intensity of infrared rays that pass through it is halved.

The laser light used in LiDAR systems is near-infrared light. The transmittance of the cover glass has a direct effect on the detection capability of the system as laser light passes through the protective cover twice, once when it is emitted and again when it is reflected and received.

Conventional covers made of resin have the characteristic of absorbing infrared rays, which reduces the amount of light emitted and received. In contrast, the near-infrared transmittance of the cover glass that AGC produces is nearly 100%.

Protection (impact resistance)

The amount of physical protection (impact resistance) that cover glass requires is one of its most important characteristics. The reason for that is because it is essential for the cover glass to be able to protect the internal components from objects flying at the LiDAR unit.

04/Materials

The conventional material for the protective covers for LiDAR was mainly resin, but that material had the problem of being easily scratched. If the cover is scratched, the transparency decreases, and consequently so does the detection capability of the system.

The conventional material for the protective covers for LiDAR was mainly resin, but that material had the problem of being easily scratched. If the cover is scratched, the transparency decreases, and consequently so does the detection capability of the system.

If our cover glass is used however, this is no longer a worry.

That’s because AGC’s cover glass uses glass with a higher hardness compared with resin or conventional glass.

As a matter of fact, in the flying stone test that our company performed (ISO 20567-1 standard), ordinary glass cracked immediately but AGC’s glass didn’t crack at all even after being hit several hundred times, and hardly even had any scratches.

Therefore, AGC’s cover glass the recommended choice to maintain LiDAR scanning performance over the long-term.

Corrosion resistance

In order to maintain the performance of LiDAR over a long period of time, the protective cover used as the housing must be made of materials that are resistant to corrosion and deterioration over time. This is especially the case when the LiDAR is to be used outdoors as it could be exposed to elements of harsh environments such as rain, wind, and UV rays.

Cover glass is extremely stable and corrosion resistant because it is made of inorganic materials, so there is very little worry about deterioration. This is in contrast with resin which is made from organic materials so its deterioration by UV rays is inevitable.

For those reasons, LiDAR covers must be corrosion resistant, and in order to maintain their performance over a long period of time, a highly stable cover glass is optimal.

Heat resistance

In cold environments, snow and frost build-up on cover glass can be expected. This build-up could block the laser beams, resulting in areas that cannot be detected by LiDAR.

Heaters are an effective way to remove the snow and frost build-up. Cover glass must be resistant to the heat generated by these heaters.

AGC’s cover glass is made to be installed with a heater with this in mind. There is no need to worry about deformation due to heat or vibrations.

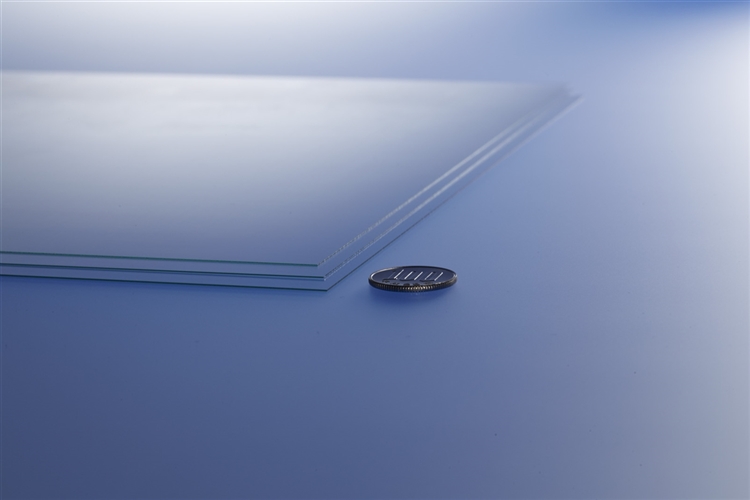

05/AGC's LiDAR cover glass

AGC produces cover glass for LiDAR applications. It has already been adopted by a LiDAR manufacturer through a European subsidiary, with the aim of entering into mass production sometime in 2022.

AGC produces cover glass for LiDAR applications. It has already been adopted by a LiDAR manufacturer through a European subsidiary, with the aim of entering into mass production sometime in 2022.

Our company’s cover glass is superior in terms of impact and abrasion resistance than conventional resin covers and can even withstand flying stones. The near-infrared light transmittance is nearly 100%, so the internal components are protected without compromising the detection accuracy of the LiDAR. Our cover glass is also heat resistant, allowing for the installation and use of heaters.

Two such glass products that our company offers are detailed below.

Specialty glass

AGC develops and manufactures specialty glass in accordance to the requirements and specifications of each customer. The high impact resistance of our cover glass was made possible by our capability of handling everything from materials development to processing and molding in-house, allowing for the accumulation and application of vast amounts of data.

Please feel free to contact us for a proposal for glass tailored to your specific requirements.

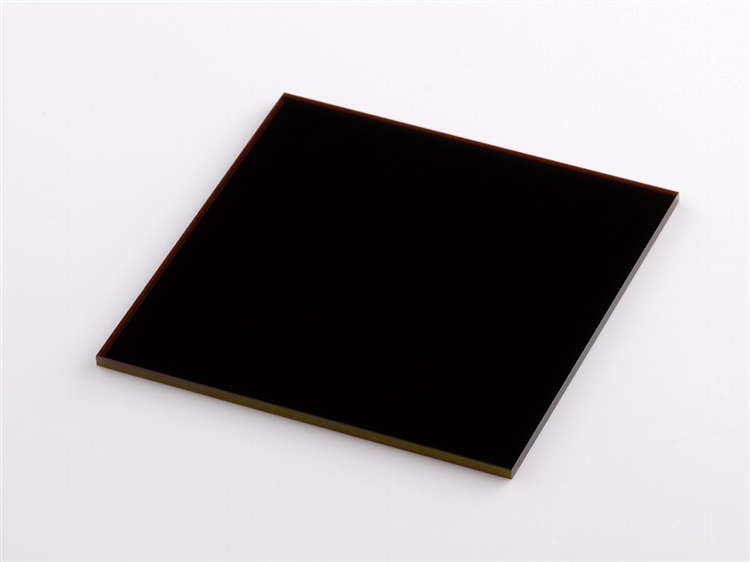

IR transmitting cover glass (Black type)

AGC also produces cover glass for LiDAR integration into vehicle windshields and B-pillar covers.

Since LiDAR uses near-infrared lasers, its cover glass does not need to be shared with window glass and can even be opaque. We developed a black cover glass for infrared transmission to blend in naturally with the vehicle body.

Even though it just looks completely black in appearance, a special coating is applied to the surface to achieve nearly 100% transmittance of near-infrared rays. It is also high in strength and scratch resistant of course, so this also serves as protection for the internal sensors.

Please feel free to contact us for solutions that accommodate your need to match vehicle body designs.

AGC’s Specialty Glass Solutions

Specialty Glass Solutions

AGC's Specialty Glass Solutions offers unique solutions to customers' various issues related to specialty glass for electronic devices.