Carrier Glass Solutions for Ultra Thin Glass Handling|AGC

AGC's Carrier Glass Technology is a groundbreaking solution for handling and processing ultra-thin glass (UTG). It overcomes a key challenge associated with UTG's incredible thinness and flexibility – its delicate nature makes it difficult to integrate into existing manufacturing processes without damaging the material

AGC's Carrier Glass Technology is a groundbreaking solution for handling and processing ultra-thin glass (UTG). It overcomes a key challenge associated with UTG's incredible thinness and flexibility – its delicate nature makes it difficult to integrate into existing manufacturing processes without damaging the material

- 1. Easy Handling of Ultra-Thin Glass (UTG)

- 2. Mechanical Lift-Off (MLO)

- What is MLO?

- Comparison with Laser Lift-Off (LLO):

- Advantages of AGC's MLO:

- 3. High heat resistance of Bonding Layer

- 4. Available in Large Sizes

- What Are the Differences Between Carrier Glass Technology with Bonding Layer and Standard Carrier Glass?

- How to Order Ultra-Thin Glass and Carrier Glass?

01/Solvable Technical Challenges

In the development of ultra-thin wafers and large panels, manufacturers face multiple challenges such as glass cracking, warping, high processing costs, and limitations in carrier systems. AGC provides innovative solutions through its advanced bonding layer and Mechanical Lift-Off (MLO) technology—enabling higher reliability, reduced equipment costs, and scalability to larger panel sizes.

-

Cracks & Warping During Carrier-Glass Transfer and Processing

- Technical Challenges We Face

- We are facing issues with cracks and warping of carrier glass during the transfer and processing of ultra-thin wafers and large panels.

- What AGC Can Solve

- By laminating with thick carrier glass, cracks and warping can be suppressed.

Since AGC’s bonding layer enables mechanical debonding (MLO) with relatively low force, it helps prevent damage to UTG and devices.

Related Case Study:Thin Glass Handling-Crack Prevention During Transfer

Related Case Study:Mitigating Thin Glass Warpage in the Deposition Process

-

Limitations of the Laser Lift-Off (LLO) Method

- Technical Challenges We Face

- Currently, laser lift-off (LLO) is used, but due to concerns about high costs and damage to UTG/devices, alternative methods are being considered for new projects.

- What AGC Can Solve

- Since MLO can be performed without expensive laser equipment, the initial investment in the process can be reduced.

As MLO does not use lasers, it helps prevent damage to UTG and devices.

Related Case Study:Laser Lift-Off Process Alternative with AGC’s MLO Technology

-

Carrier System Unable to Withstand High-Temperature Processing

- Technical Challenges We Face

- The existing carrier system cannot withstand high-temperature processes.

- What AGC Can Solve

- AGC’s bonding layer can withstand temperatures up to approximately 400 ℃.

-

Scaling Up to Larger Panel Sizes

- Technical Challenges We Face

- We would like to scale up to large panels, but it is difficult with the existing carrier system.

- What AGC Can Solve

- AGC’s glass with bonding layer can accommodate sizes up to 920 × 730 mm (larger sizes can be discussed upon request).

Since MLO does not use lasers, large-scale laser equipment is not required.

02/Technology Overview|Thin Carrier Glass Temporary Bonding Solutions

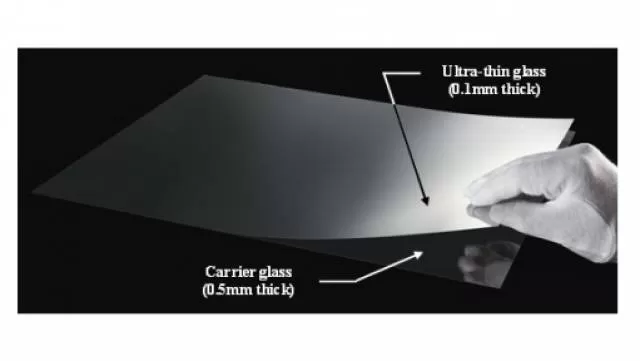

This technology's core is a lamination process that bonds an ultra-thin layer of UTG, less than 0.1 mm thick, onto a sturdier carrier glass. A specialized bonding layer is strategically placed between these two glass components, creating a robust and stable composite material. This composite substrate retains the exceptional properties of UTG, such as transparency, heat resistance, and electrical insulation, while significantly enhancing its manageability.

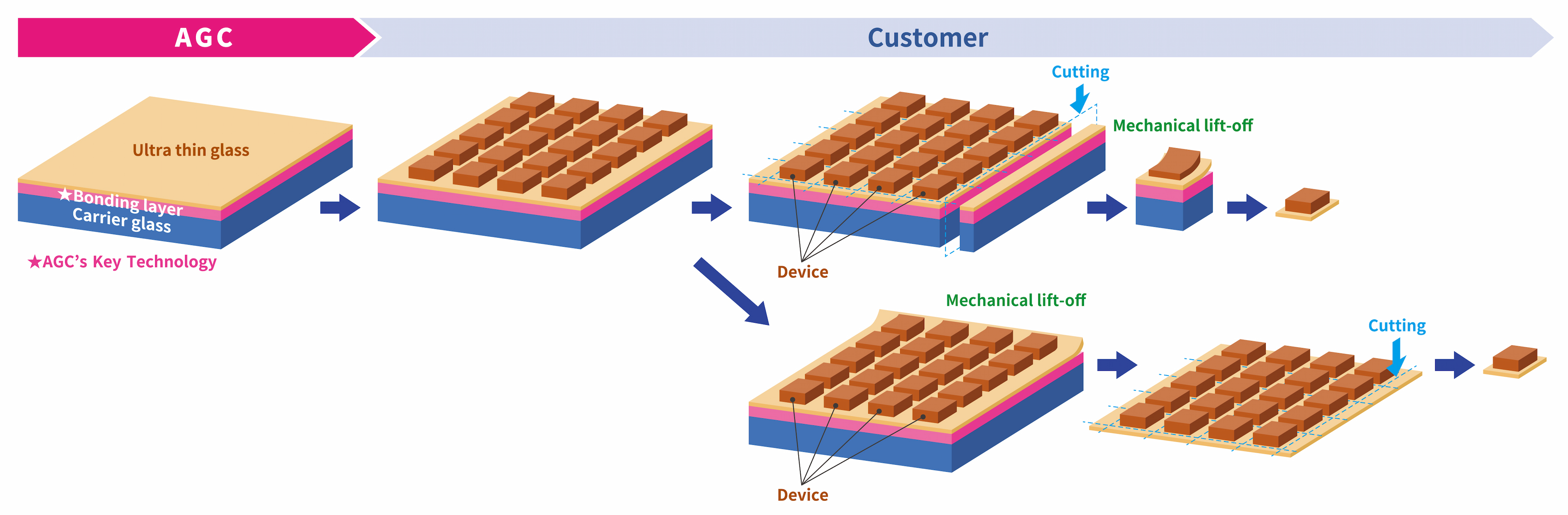

Integrating AGC's Carrier Glass Technology into the manufacturing process is relatively straightforward. The carrier glass with the bonded UTG is supplied to the customer, who then incorporates it into their product development cycle. Once the desired device is formed on the UTG layer, the carrier glass can be removed through a process known as Mechanical Lift Off (MLO). It leaves behind the patterned UTG that is ready for integration into the final product.

The process can be summarized as follows:

1. AGC Production: Ultra-thin glass is bonded to carrier glass using a specialized bonding layer.

2. Customer Integration: The laminated glass substrate is delivered to the customer.

3. The customer forms the devices on the ultra-thin glass layer.

4. MLO Process: The carrier glass is removed through mechanical lift-off, leaving the patterned ultra-thin glass behind.

By providing a reliable and efficient method for handling UTG, AGC's Carrier Glass Technology empowers manufacturers to unlock the full potential of this remarkable material in a wide range of applications.

AGC's Carrier Glass Technology incorporates several key features contributing to its effectiveness in handling and processing ultra-thin glass (UTG).

1. Easy Handling of Ultra-Thin Glass (UTG)

One of this technology's primary advantages is its ability to simplify the handling of UTG. AGC has transformed a highly fragile material into a more manageable substrate by laminating the delicate UTG onto a thicker carrier glass.

One of this technology's primary advantages is its ability to simplify the handling of UTG. AGC has transformed a highly fragile material into a more manageable substrate by laminating the delicate UTG onto a thicker carrier glass.

This innovation eliminates the need for specialized handling equipment and reduces the risk of damage during transportation and manufacturing processes. Consequently, manufacturers can streamline operations, reduce production costs, and increase efficiency. This enhanced handling capability is a cornerstone of AGC's Carrier Glass Technology, making it a valuable asset for industries working with ultra-thin glass.

2. Mechanical Lift-Off (MLO)

What is MLO?

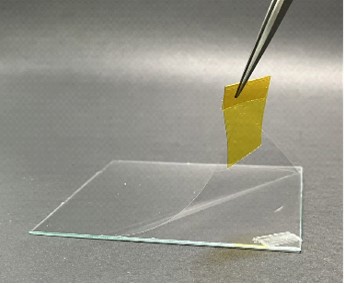

Mechanical Lift-Off (MLO) is a process used to separate an ultra-thin layer of UTG (Ultra-Thin Glass) from its carrier glass through mechanical (or physical) means. This method involves the application of a mechanical force to peel away the ultra-thin layer from the sturdier carrier glass, preserving the integrity of the delicate UTG.

Mechanical Lift-Off (MLO) is a process used to separate an ultra-thin layer of UTG (Ultra-Thin Glass) from its carrier glass through mechanical (or physical) means. This method involves the application of a mechanical force to peel away the ultra-thin layer from the sturdier carrier glass, preserving the integrity of the delicate UTG.

Comparison with Laser Lift-Off (LLO):

While MLO uses mechanical force for separation, Laser Lift-Off (LLO) is another method that relies on laser energy to achieve the same result. However, LLO has significant drawbacks, including high initial and running costs. Additionally, LLO poses quality issues, such as the potential to damage the delicate devices during the separation process, making it a less favorable option in certain applications.

Advantages of AGC's MLO:

One of the challenges with MLO is that if the separation force is too strong, there is a risk of damaging the ultra-thin layer or the device. AGC's lamination process addresses this by enabling separation with a low separation force, significantly reducing the risk of damage to the UTG or the associated devices. This low-force separation makes AGC's MLO process particularly advantageous for applications requiring high precision and the preservation of delicate materials.

3. High heat resistance of Bonding Layer

A critical component of AGC's Carrier Glass Technology is the bonding layer, which exhibits exceptional heat resistance and can endure temperatures of approximately 400°C. This thermal resilience is paramount for the technology's efficacy. Numerous manufacturing processes, such as annealing, tempering, and certain coating applications, necessitate exposure to elevated temperatures.

The bonding layer's ability to withstand such conditions ensures the integrity of the laminated substrate, preventing delamination or degradation of the ultra-thin glass. Consequently, AGC's Carrier Glass Technology offers manufacturers a reliable and durable solution that can seamlessly integrate into existing production lines without compromising product quality or yield.

4. Available in Large Sizes

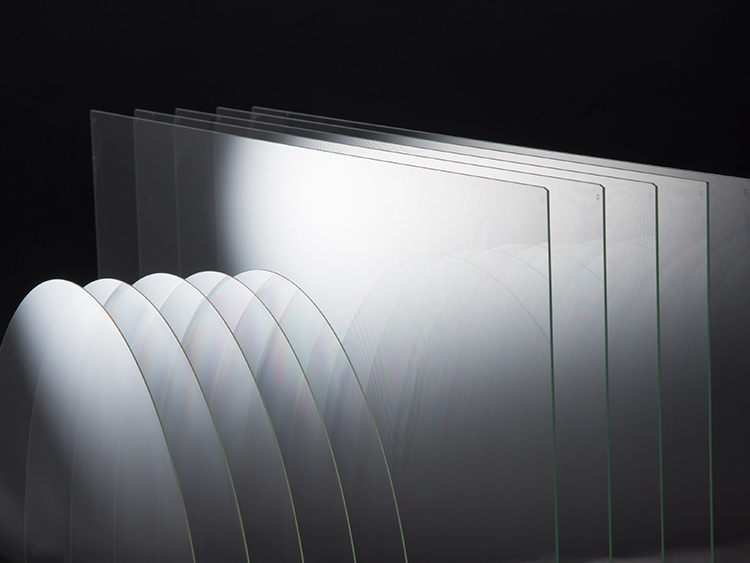

AGC offers large-sized carrier glass technology using large-format glass produced by the float process, to meet the growing demand for large-scale applications and improve process efficiency through large substrates. This capability enables manufacturers to process larger sheets of UTG without compromising quality or efficiency.

By eliminating the constraints of smaller substrate sizes, AGC empowers manufacturers to explore new design possibilities and cater to the growing market for larger-scale devices. This scalability is a testament to AGC's commitment to providing comprehensive solutions that meet the evolving needs of the industry.

03/FAQs

How to Order Ultra-Thin Glass and Carrier Glass?

AGC provides a convenient solution by offering ultra-thin glass, bonding layer and carrier glass as a combined product. This approach simplifies the ordering process for customers, as they no longer need to source these components separately.

Do you provide samples or support small-scale trial production?

Yes, it is possible. We also handle prototyping.

What is the lead time for samples?

Lead time depends on the customer’s specifications.

We can handle small quantities for prototyping with quick turnaround.

What is the size and thickness range you can support?

We can handle sizes up to 920 × 730 mm. For larger sizes, please contact us.

We can support ultra-thin glass thicknesses down to 0.05 mm, carrier glass thicknesses approximately 0.3mm to 1.0mm.

Does AGC offer other carrier glass technologies?

We offer carrier glass technology for semiconductor packaging. If you are interested, please click the link below.

Other AGC's Carrier Glass Technology

Glass substrate for semiconductor packaging

Unlike AGC's Carrier Glass Technology with Bonding Layer, which focuses on handling delicate ultra-thin glass, this product emphasizes high flatness and smoothness, critical for the precision of semiconductor packaging. Supporting various wafer sizes (such as φ300 mm) and panel sizes, AGC’s glass substrates ensure reliable performance in processes requiring high-quality carrier glass, including those with special features like notches, serial numbering, and ID marking.

04/Contact Us

Ready to streamline your manufacturing process and explore the benefits of ultra-thin glass? Contact us today to learn how AGC’s Carrier Glass Technology can enhance your product development, improve handling efficiency, and empower your innovative designs.

Contact us today to learn more

about AGC's Carrier Glass