Satellite Solar Panel Cell Cover Glass | AGC EG-S1

AGC's satellite solar cover glass, or EG-S1, is a cutting-edge solution that can meet the demanding requirements of satellite solar panels.

AGC's satellite solar cover glass, or EG-S1, is a cutting-edge solution that can meet the demanding requirements of satellite solar panels.

EG-S1 has excellent UV-shielding properties and electron beam resistance, contributing to the high reliability and efficiency of space solar cells used in satellites and other applications, and supporting various space missions in the future.

01/AGC’s Satellite Solar Cell Cover Glass – EG-S1

EG-S1 is a specialty glass engineered for demanding applications such as satellite solar cell cover glass, offering exceptional optical properties, mechanical strength, and environmental durability.

Available in a wide range of thicknesses — down to 0.05 mm — it supports ultra-thin, lightweight designs, and high strength, high radiation resistance designs.

Custom cutting is available for sizes up to approximately 500 mm in length or width, in a variety of shapes including polygons and wafers.

EG-S1 can be enhanced with a selection of advanced surface treatments such as AR (anti-reflective) coating, ITO conductive coating, silver deposition coating, and UV-reflective coating, as well as chemical strengthening for improved impact and scratch resistance.

These capabilities make EG-S1 a versatile and reliable choice for next-generation space and high-performance applications.

02/Features

AGC's EG-S1 is engineered to provide exceptional protection and performance for satellite solar panels. Let's dive deeper into its key features:

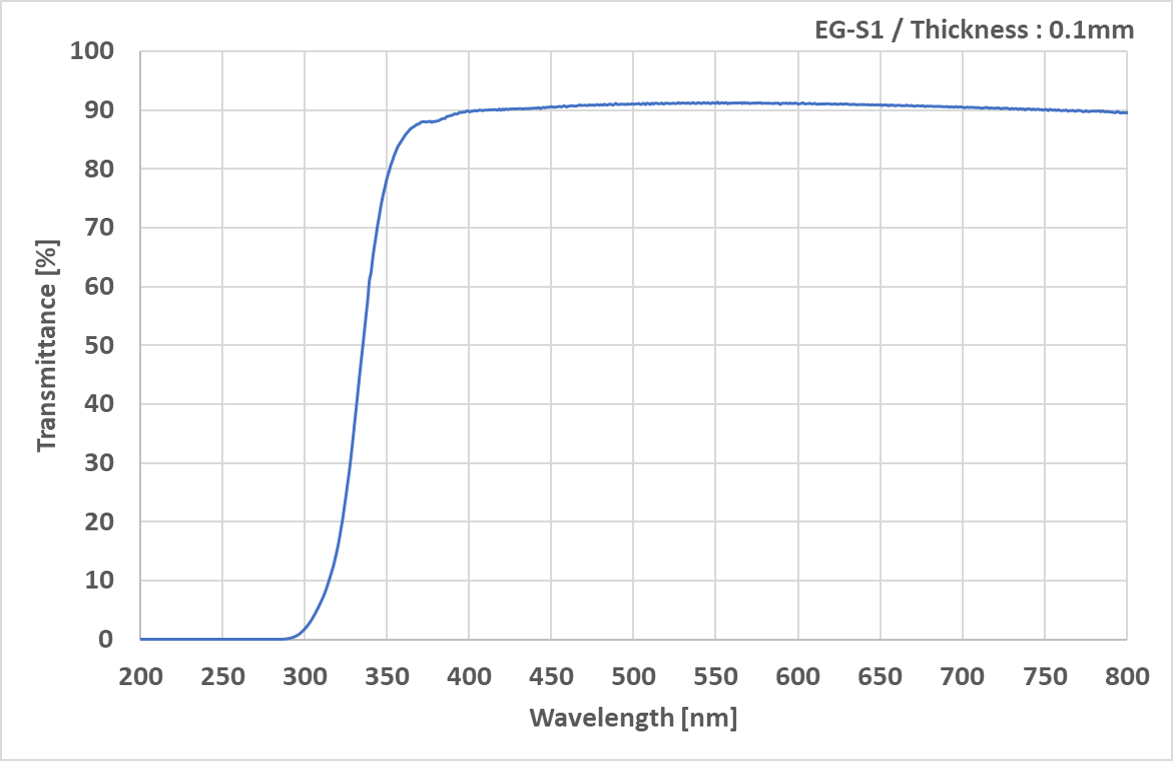

Shielding Ultraviolet (UV)

EG-S1 is formulated to shield solar cells from harmful ultraviolet (UV) radiation. This protection is crucial for maintaining the efficiency and longevity of solar panels, ensuring they perform optimally throughout their mission lifespan.

EG-S1 is formulated to shield solar cells from harmful ultraviolet (UV) radiation. This protection is crucial for maintaining the efficiency and longevity of solar panels, ensuring they perform optimally throughout their mission lifespan.

In space, solar panels are exposed to high levels of UV radiation, which can degrade the efficiency of solar cells over time. EG-S1's UV shielding capabilities help mitigate this degradation, ensuring satellite solar panels maintain their performance and reliability.

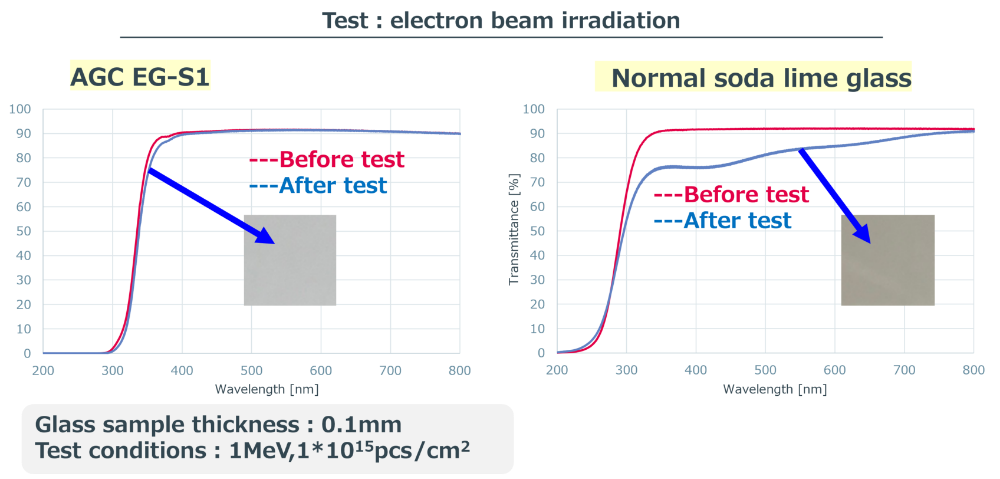

Shielding Electron Beam

In addition to UV radiation, EG-S1 shields against damaging electron beam radiation. This feature is essential for protecting solar cells from the effects of charged particles in space, which can cause degradation and malfunction.

These particles, which are emitted by the sun and cosmic rays, can penetrate solar panels and cause degradation of the cells over time. EG-S1's electron beam shielding capabilities help mitigate this degradation, ensuring that solar panels remain operational and efficient throughout their mission lifespan.

In addition, common glass is known to color itself by electron beams. This decrease in the transmittance of the cover glass reduces the efficiency of the solar cell. EG-S1, on the other hand, is able to suppress coloration even when exposed to electron beams, thus contributing to continuous high efficiency without affecting the efficiency of the solar cell.

Variety of thickness and cutting design

EG-S1 can be produced in a wide range of thicknesses and cut into arbitrary shapes according to customer needs. It supports ultra-thin sheets down to 0.05 mm, contributing to weight reduction and flexibility of solar cells.

Custom cutting is available for sizes up to approximately 500 mm in length or width, in shapes such as polygons or wafers. For larger sizes, please contact us.

Because of its high customizability, EG-S1 can meet the needs of various satellite projects.

03/Applications

The main applications of EG-S1 are listed below. Plus, we believe that EG-S1 can contribute to various space cover applications other than those. Please feel free to contact us if you are considering other uses of this satellite solar cell cover glass.

Satellite Solar Cell

One of the primary applications of EG-S1 is in satellite solar panels. These panels are essential for powering satellites in space, but they are exposed to high levels of radiation that can degrade their efficiency over time. EG-S1's UV and electron beam shielding capabilities help protect solar cells from this radiation, ensuring they remain efficient and reliable throughout the satellite's mission.

Optical Solar Reflectors

We believe that EG-S1 can contribute to optical solar reflectors, which are essential for spacecraft thermal management. These reflectors help regulate the temperature inside the spacecraft by reflecting excess heat away.

04/Technical Data

Resistance to UV & E-Beam

EG-S1 demonstrates exceptional resistance to ultraviolet (UV) radiation and electron beam irradiation, making it highly suitable for use in demanding environments such as space. The graph above illustrates the comparative performance of AGC EG-S1 and normal soda lime glass under these conditions.

AGC EG-S1 maintains its integrity and performance significantly better than normal soda lime glass after UV and electron beam irradiation exposure. This resilience ensures that solar panels protected by EG-S1 can withstand harsh space conditions and operate efficiently over extended periods.

Detailed test conditions and results for radiation resistance, including UV, electron beam, and proton beam, can be provided upon request.

05/FAQs

What is the standard thickness range for EG-S1, and is mass production possible for ultra-thin sheets of 0.1 mm?

We can support thicknesses down to 0.05 mm.

What is the maximum size (length × width) and shape (polygon, circular, etc.) that can be custom cut?

We can handle sizes up to approximately 500 mm. For larger sizes, please contact us.

What is the workflow and lead time from the initial quotation to mass production adoption?

Lead time depends on the customer’s specifications.

We can handle small quantities for prototyping with quick turnaround.Mass production can also be delivered with short lead times.

Is it possible to provide sample workpieces? Also, do you handle small-lot prototyping?

Yes, it is possible. We also handle prototyping.

Can I obtain the test conditions and results for radiation resistance (UV, electron beam, proton beam)?

Detailed data can be provided upon request.

Is it possible to apply additional coatings, such as anti-reflective (AR) or conductive coatings, before mass production?

We can provide AR coating, ITO coating, silver deposition coating, and UV-reflective coating. We can also accommodate chemical strengthening. For more details, please see the information at the Additional Functional Options section.

If the glass is damaged after solar cell bonding, is on-site rework or replacement possible?

We do not offer on-site rework or replacement, but we can supply replacement glass for repair purposes.

06/Additional Functional Options for EG-S1

・AR (Anti-Reflective) coating– Reduces surface reflection and increases light transmission, improving solar cell efficiency.

・ITO coating– Adds electrical conductivity while maintaining high transparency, enabling anti-static protection and transparent electrodes.

・Silver deposition coating– Provides high reflectivity and conductivity for infrared control and EMI shielding.

・UV-reflective coating– Reflects and blocks ultraviolet light to protect internal components from degradation.

・Chemical strengthening– Enhances impact and scratch resistance, improving durability even in ultra-thin sheets.

Contact us!

AGC is a leading provider of innovative glass solutions focusing on high-performance materials for space applications. Our satellite solar cell cover glass, EG-S1, is specially designed for the demanding space exploration requirements, offering exceptional durability and performance.

To learn more about AGC's satellite solar cell cover glass, EG-S1, and how it can benefit your project, contact us today for more information.

Contact us today to learn more

about AGC's EG-S1