Tempered Cover Glass for Solar Panel - Hail Resistant Glass for Enhanced Protection

- Hail-Resistant Design

- Minimal Thickness

- What Kind of Glass is Used for Solar Panel Cover?

- Float Glass

- Patterned Glass

- What Glass Strengthening Method Is Used For Tempered Cover Glass?

- Chemical Strengthening

- Physical Strengthening

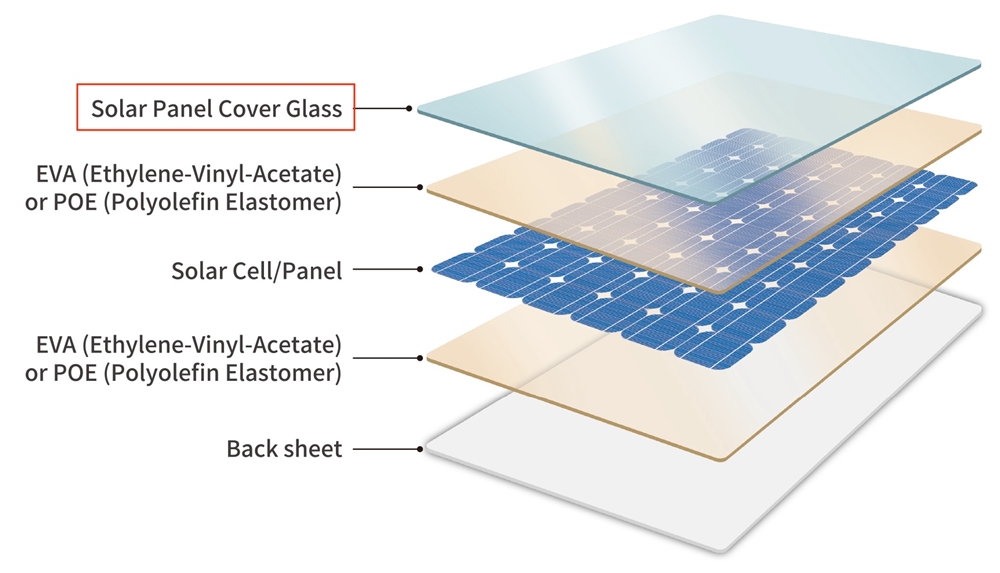

01/What Is Cover Glass for Solar Panels?

Cover glass for solar panels is a crucial component that serves as a protective barrier for the photovoltaic cells, which convert sunlight into electricity. It is typically made of tempered glass, specially treated to be more durable and resistant to environmental stressors.

Cover glass for solar panels plays a vital role in the efficiency and longevity of solar panel systems. In addition to providing a protective barrier, it also serves as a transparent substrate that allows sunlight to pass through to the photovoltaic cells while protecting them from external elements such as dust, moisture, and debris.

Tempered glass for cover glass is essential due to its superior strength and durability compared to regular glass. Tempering involves heating the glass to a high temperature and then rapidly cooling it, which creates compressive stress layers to increase the strength of the glass and more resistant to breakage.

Overall, cover glass is a critical component of solar panel systems, providing protection and durability to ensure the long-term performance of the panels. Its use of tempered glass enhances its ability to withstand environmental stresses and protect the underlying photovoltaic cells, ultimately contributing to solar energy systems' overall efficiency and reliability.

02/Why Solar Panel Cover Glass (Hail Resistant Cover Glass) is Needed?

These days, extreme weather events with hailstorms are becoming more frequent worldwide, and the number of damage cases is increasing. Consequently, the need for cover glass for solar panels stems from the vulnerability of photovoltaic cells to damage from various sources, including hail. Extreme weather events, such as hailstorms, can cause significant damage to solar panels, leading to reduced efficiency and costly repairs or replacements.

One notable incident highlighting the need for hail-resistant cover glass occurred at the Midway Solar Project in Texas in 2019.

The project suffered extensive damage, with over 400,000 modules damaged or destroyed, resulting in a total insurance loss of 70 million US dollars.

To address this issue, researchers and manufacturers are working on improving the hail resistance of solar panel. It includes developing cover glass that significantly enhances strength compared to existing options to prevent catastrophic damages and advance the solar industry.

03/Tempered Cover Glass for Solar Panel by AGC

AGC, a leading glass manufacturer, offers tempered cover glass for solar panels. This glass is engineered to meet the solar industry's demanding requirements, providing durability and performance.

AGC, a leading glass manufacturer, offers tempered cover glass for solar panels. This glass is engineered to meet the solar industry's demanding requirements, providing durability and performance.

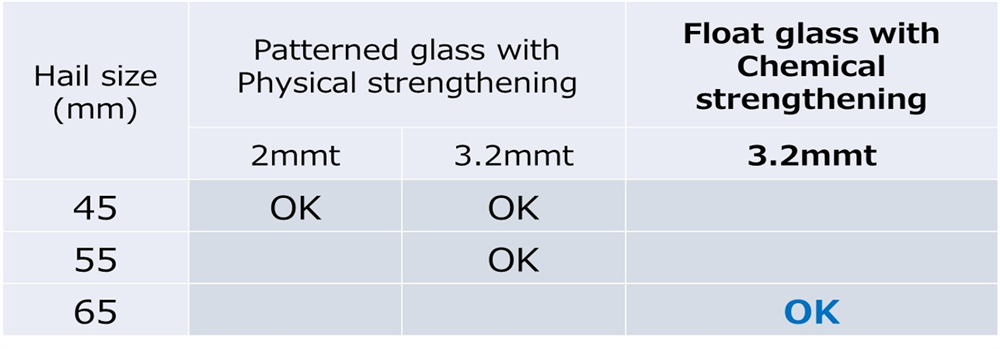

Hail-Resistant Design

AGC's tempered cover glass is designed to withstand impact from hailstones of various sizes and velocities, ensuring that solar panels remain protected even in harsh weather conditions.

This hail-resistant design is the result of extensive testing and research, including a collaboration with Erthos, Inc. and RETC, LLC, where a prototype solar panel equipped with chemically strengthened float glass 3.2mmt passed a hail test with a hail size of 65mm (KE 89J). Additionally, the patterned glass was tested, with the 3.2mmt glass passing hail sizes of 45-55mm, and the 2.0mmt glass passing hail sizes of 35-45mm.

Minimal Thickness

AGC's tempered cover glass is designed to be as thin as possible while maintaining strength. This minimal thickness helps reduce the solar panels' overall weight, making them easier to handle and install.

The minimal thickness of AGC's tempered cover glass also contributes to the overall efficiency of solar panel systems. The thinner glass allows more sunlight to reach the photovoltaic cells, increasing the panels' energy conversion efficiency.

This improved efficiency not only maximizes the panels' energy output but also enhances the return on investment for solar panel installations. Additionally, the panels' reduced weight makes them more versatile and suitable for a wider range of applications, including rooftop and installations.

04/Contact Us

Solar panels are a significant investment, ensuring their longevity and performance is crucial. AGC's hail-resistant tempered cover glass is designed to protect your solar panels from damage, ensuring they continue to generate clean, renewable energy for years to come.

Contact AGC today to learn more about how our hail-resistant tempered solar panel cover glass can enhance the lifespan and efficiency of your solar panels.

05/FAQs

What Kind of Glass is Used for Solar Panel Cover?

Several types of glass are commonly employed as the cover glass for solar panels, each with unique properties and suitability for different applications.

Float Glass

Float glass is a type of solar panel cover glass manufactured by floating molten glass on a bed of molten metal, typically tin, to create a uniform thickness. It is known for its large-scale production capabilities and relatively low cost compared to other types of glass. Due to its cost-effectiveness and ease of mass production, float glass is often used in solar cell cover glass for compound solar cells.

Float glass is a type of solar panel cover glass manufactured by floating molten glass on a bed of molten metal, typically tin, to create a uniform thickness. It is known for its large-scale production capabilities and relatively low cost compared to other types of glass. Due to its cost-effectiveness and ease of mass production, float glass is often used in solar cell cover glass for compound solar cells.

Due to its manufacturing process, float glass is a preferred choice for solar panel applications. The ball drop test results reveal that float glass with chemically strengthened exhibits exceptional fracture energy making it highly resistant to impact. This resilience is crucial for solar panels, which are often exposed to environmental stresses.

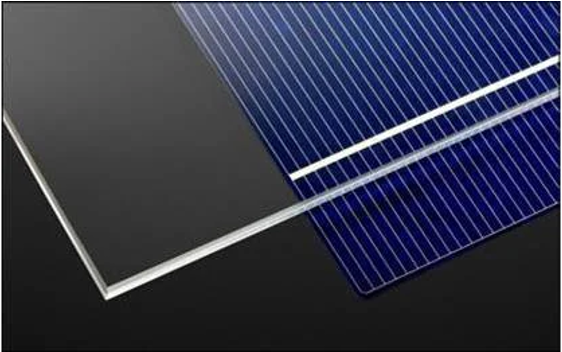

Patterned Glass

Patterned glass is another type of solar panel cover glass commonly used for solar panel covers. Its textured surface characterizes it, which can help improve light diffusion and reduce glare.

Patterned glass is another type of solar panel cover glass commonly used for solar panel covers. Its textured surface characterizes it, which can help improve light diffusion and reduce glare.

Patterned glass is often chosen for its ability to diffuse light, reduce glare, and improve the uniformity of light distribution on solar panels. This characteristic can enhance the overall efficiency of solar panels by ensuring that a greater portion of the sunlight is converted into electricity. Patterned glass remains a viable option for solar panel covers, especially in applications where light diffusion, anti glare, and low cost is a priority.

What Glass Strengthening Method Is Used For Tempered Cover Glass?

Tempered cover glass is strengthened using two primary methods: chemical strengthening and physical strengthening.

Chemical Strengthening

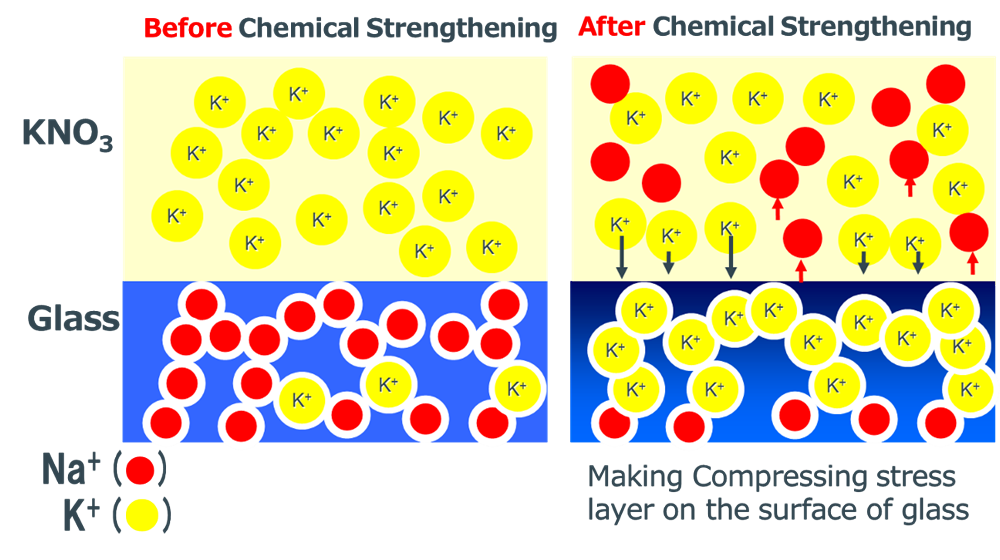

Chemical strengthening involves immersing the glass in a chemical bath containing potassium (K+). This process replaces smaller ions in the glass surface with larger ions from the bath, creating a compressive stress layer on the surface of the glass. This compressive stress layer improves the glass's resistance to fracture, making it more durable and suitable for applications where strength is critical.

Chemical strengthening involves immersing the glass in a chemical bath containing potassium (K+). This process replaces smaller ions in the glass surface with larger ions from the bath, creating a compressive stress layer on the surface of the glass. This compressive stress layer improves the glass's resistance to fracture, making it more durable and suitable for applications where strength is critical.

Chemical strengthening is a highly effective method for improving the durability and strength of glass, making it an ideal choice for demanding applications such as smartphone cover glass. The process creates a surface layer significantly stronger than the glass interior, providing enhanced protection against impact and environmental stressors.

The increased strength and durability ensure that solar panels equipped with chemically strengthened glass can withstand harsh conditions and maintain their performance over an extended period, maximizing their lifespan and efficiency.

Physical Strengthening

Physical strengthening, also known as thermal tempering, involves heating the glass to just below its softening point and then rapidly cooling it. This process creates a compressive stress layer on the outer surface of the glass, increasing its strength and resistance to impact. Physical strengthening is commonly used for glass that requires high strength and impact resistance, such as tempered cover glass for solar panels.

AGC has glass strengthening technologies developed over the years, and can propose high-strength cover glass solutions that meet customers' requirements.