Thin Glass Handling Technology: Crack Prevention in the Transfer Process

As electronic devices continue to evolve toward lighter, thinner, and more sophisticated designs, manufacturers face increasing challenges in handling ultra‐thin glass substrates. For glass thinner than 0.3 mm, maintaining high yields during transfer processes becomes increasingly difficult due to the heightened risk of cracking.

This case study explores how AGC’s carrier glass technology offers a breakthrough solution for thin glass handling, effectively preventing thin glass cracks and improving production yield.

01/Background: The Challenge of Handling Ultra-Thin Glass

With the growing demand for high-performance materials in smartphones, displays, sensors, and optical components, thin single-layer glass (≤ 0.3 mm) has become essential. However, as the glass becomes thinner, its rigidity decreases significantly, making it more susceptible to cracking during handling and transportation within production lines.

With the growing demand for high-performance materials in smartphones, displays, sensors, and optical components, thin single-layer glass (≤ 0.3 mm) has become essential. However, as the glass becomes thinner, its rigidity decreases significantly, making it more susceptible to cracking during handling and transportation within production lines.

During transfer between processing stages, thin glass often suffers from mechanical and process-induced stresses, such as:

・Uneven suction pressure or release shocks from vacuum pads

・Micro-vibrations or impacts from conveyors and robots

・Deflection or bending due to insufficient support

・Edge chipping and the propagation of microscopic surface defects

At thicknesses below 0.2 mm, glass can deform under its own weight, making stable handling almost impossible with conventional systems. Even at 0.3 mm, yield losses are common and often require costly equipment modifications or strict process adjustments to maintain acceptable performance.

Cracking during transfer not only causes direct product loss but also leads to line downtime, additional cleaning, and reduced overall productivity, significantly affecting cost efficiency.

02/AGC’s Solution: Carrier Glass for Reliable Thin Glass Handling

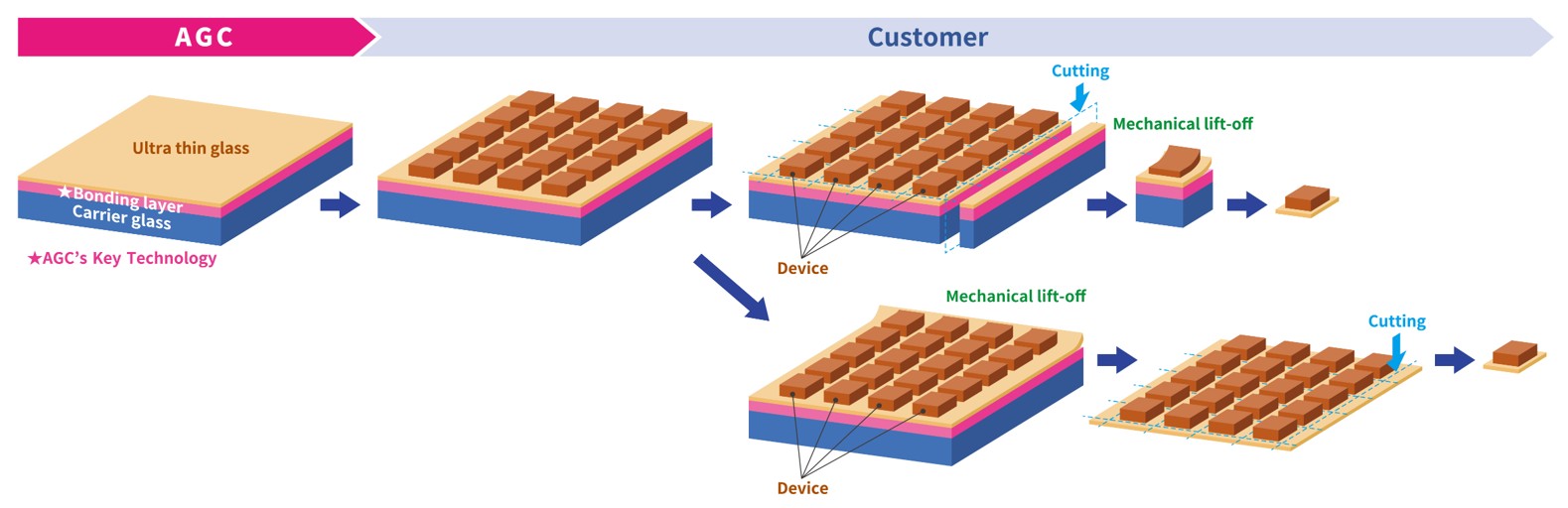

To overcome these challenges, AGC has developed an innovative carrier glass solution that enables safe, reliable handling of thin glass across multiple manufacturing stages.

A carrier glass acts as a temporary support substrate, allowing ultra-thin glass to be processed and transferred without exposure to direct mechanical stress.

This approach provides multiple advantages:

・Crack Prevention: The ultra-thin glass is firmly supported by the rigid carrier glass, preventing mechanical stress and significantly reducing the risk of cracking.

・Stable Transfer: Enables standard suction and handling parameters similar to conventional thicker glass.

・Higher Yield: Minimizes cracking, resulting in improved process stability and higher throughput.

・High Heat Resistance: The bonding layer exhibits exceptional heat resistance and can withstand temperatures of approximately 400°C.

・Compatibility: Adaptable to existing manufacturing lines with minimal equipment modifications.

For glass thinner than 0.2 mm, AGC’s carrier glass technology makes it possible to achieve stable transfer operations that were previously considered impractical, greatly enhancing yield and operational efficiency.

Learn More About AGC’s Glass Handling Technology

Learn More About AGC’s Glass Handling Technology

03/Enabling Direct Processing of Thin Glass Without Slimming or Back-Grinding (BG)

Traditionally, achieving the required thinness for glass substrates has relied on additional processes such as slimming or back‐grinding (BG). These steps, however, tend to increase manufacturing costs and may introduce quality concerns such as micro‐defects or surface damage.

By leveraging AGC’s carrier glass handling technology, manufacturers can not only handle thin glass safely but also process and transfer glass substrates directly—eliminating the need for separate thinning steps such as slimming or BG. This simplifies the production line, reduces the risk of cracking, and improves overall yield. Furthermore, omitting the slimming or BG step contributes to lower equipment and process costs while maintaining consistent product quality.

While the full cost advantages are still under evaluation, initial results indicate that bypassing mechanical thinning processes can also help reduce defects typically caused by conventional slimming or BG.

04/Explore AGC’s Advanced Glass Technologies

AGC continues to pioneer advanced glass technologies that enable safer, more reliable, and higher‐yield manufacturing for next‐generation electronic devices.

To learn more about AGC’s carrier glass technology for thin glass handling, please visit the official product page.