Laser Lift-Off Process Alternative With AGC’s Mechanical Lift-Off Technology

Due to the continued demand for thinner, lighter, and more flexible materials in display and semiconductor production, manufacturers are increasingly exploring efficient and cost-effective methods for separating functional layers from carrier substrates.

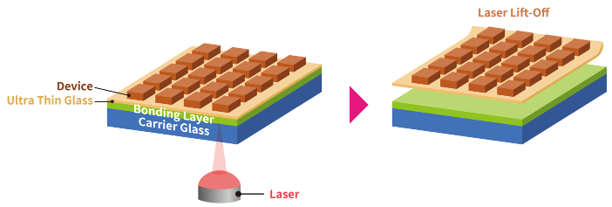

Traditionally, Laser Lift-Off (LLO) systems have been widely adopted for this process, but their high equipment costs and complex maintenance requirements present major challenges for production scalability.

This case study explores how AGC’s Mechanical Lift-Off (MLO) technology provides a practical and economical alternative to laser systems, reducing capital expenditure while maintaining high separation quality and throughput.

01/Background: The Challenge of High-Cost LLO Systems

In the fabrication of flexible displays, sensors, and microdevices, it is often necessary to separate thin glass or film layers from a rigid carrier substrate.

In the fabrication of flexible displays, sensors, and microdevices, it is often necessary to separate thin glass or film layers from a rigid carrier substrate.

While LLO technology offers precise control and minimal thermal damage, it also presents significant barriers:

・High Initial Investment: Laser equipment typically requires an investment of hundreds of millions of yen.

・High Running Costs: Maintenance, calibration, and laser component replacement lead to recurring expenses.

・Thermal Stress Issues: Localized heating can cause material deformation or degradation in sensitive films.

・Throughput Limitations: Laser scanning speed constrains overall productivity.

As a result, manufacturers are seeking a more cost-efficient solution that maintains production quality while reducing total cost of ownership.

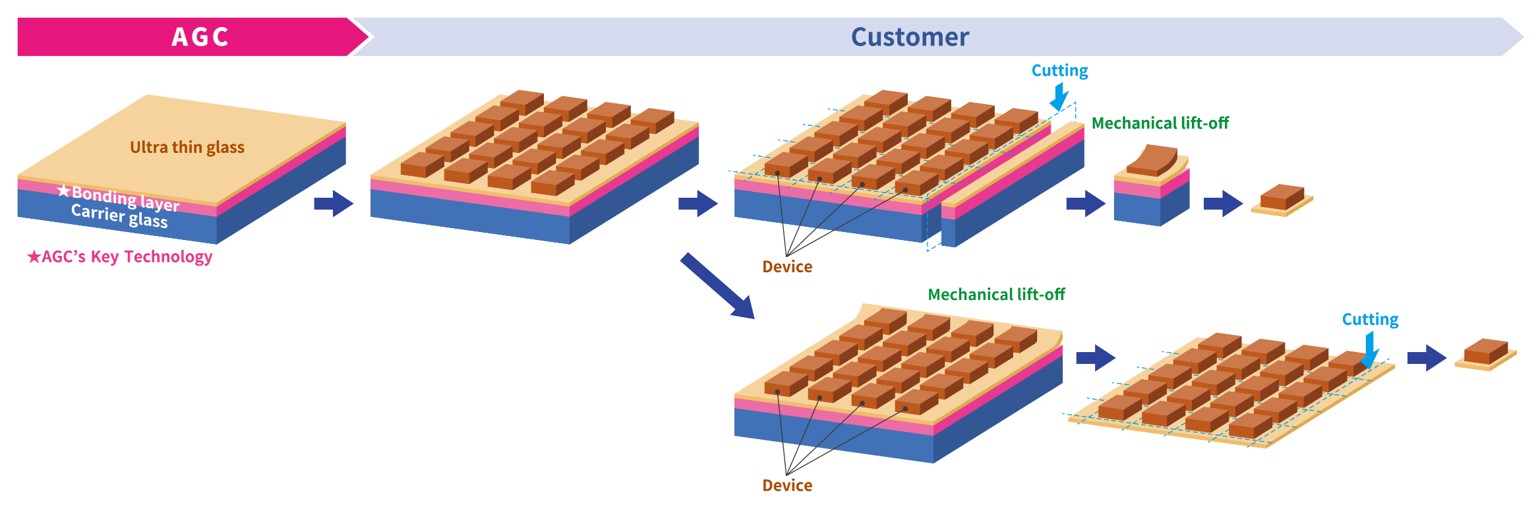

02/AGC’s Solution: MLO Technology

To address these challenges, AGC has developed MLO—an innovative separation method that eliminates the need for laser-based systems.

It enables the clean and uniform detachment of thin functional layers from carrier glass through a controlled mechanical process without relying on high-cost optical components.

Key Advantages:

・Significant Cost Reduction: MLO eliminates the running costs associated with laser equipment.

・Stable Separation Quality: Mechanical detachment minimizes thermal stress, preserving material integrity.

・Process Flexibility: The technology is compatible with various film and substrate combinations used in flexible electronics, with a bonding layer that offers high heat resistance and excellent chemical resistance.

・Scalable Implementation: MLO integrates easily into existing production lines with minimal modification.

・Improved Maintenance Efficiency: The simple structure reduces downtime and maintenance frequency.

By replacing the laser-based separation stage with AGC’s MLO technology, manufacturers can expect substantial capital savings and greater operational flexibility while maintaining product performance and yield.

03/Explore AGC’s Advanced Glass Technologies

AGC continues to pioneer advanced glass technologies that enable safer, more reliable, and higher‐yield manufacturing for next‐generation electronic devices.

To learn more about AGC’s carrier glass technology for thin glass handling, please visit the official product page.