AGC's Soda lime float glass, AS2

Float glass is an outstanding material that has become indispensable in our daily lives. AGC is a global leader in glass technology and innovation, and has developed AS2, a high-quality soda-lime glass produced by the float process. Thanks to its unique characteristics and exceptional performance, AS2 is used across a wide range of industries. Its primary applications include glass for electronic devices, thin sheet glass for the architectural sector, and automotive glazing, and we welcome inquiries from customers in these areas. In this article, we explain what float glass is, highlight the unique features and key applications of AGC’s AS2, provide answers to frequently asked questions, and outline how to contact us for inquiries and orders.

Float glass is an outstanding material that has become indispensable in our daily lives. AGC is a global leader in glass technology and innovation, and has developed AS2, a high-quality soda-lime glass produced by the float process. Thanks to its unique characteristics and exceptional performance, AS2 is used across a wide range of industries. Its primary applications include glass for electronic devices, thin sheet glass for the architectural sector, and automotive glazing, and we welcome inquiries from customers in these areas. In this article, we explain what float glass is, highlight the unique features and key applications of AGC’s AS2, provide answers to frequently asked questions, and outline how to contact us for inquiries and orders.

- Distinctive Features of AS2

- Wide range of thicknesses

- High flatness

- High heat& weather resistance

- High versatility

- Major Applications of AS2

- TN/STN LCD Panels

- Touch panel/cover glass for electronic devices

- Mirror substrates

- Carrier substrates for electronic components

- What distinguishes your float glass as "High-Quality"?

- What are the available thickness options and dimensions for your float glass?

- Do you offer any coatings or treatments, such as anti-reflective or chemical strengthening options?

- How can I get more detailed information about AS2?

01/AGC's High Quality Soda lime float glass, AS2

AGC's AS2 is a remarkable high-quality soda-lime glass by float process that stands out due to its distinctive features. Let's delve into these features to understand why AS2 is a preferred choice for various applications:

Distinctive Features of AS2

Wide range of thicknesses

AS2 offers a versatile range of thickness, from as thin as 0.23mm to 6mm.

AS2 offers a versatile range of thickness, from as thin as 0.23mm to 6mm.

This wide range makes it adaptable for a multitude of applications.Moreover,AGC can consult for even thinner plate of thickness of 0.2mm or less.

High flatness

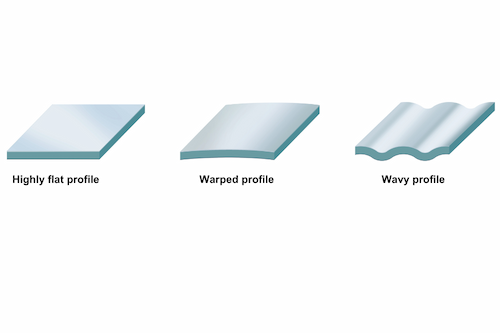

One of the key attributes of AS2 is its flatness. This means the glass has low warpage and waviness, ensuring it stays perfectly flat even in large sheets. High flatness is crucial for applications where variations can result in visual defects or functionality issues.

One of the key attributes of AS2 is its flatness. This means the glass has low warpage and waviness, ensuring it stays perfectly flat even in large sheets. High flatness is crucial for applications where variations can result in visual defects or functionality issues.

Traditionally, even when polishing processing is necessary for flattening, the use of AS2 can potentially contribute to cost reductions in processing by enabling operations with no polish or a low-polish rate. This implies that less polishing is required, which not only reduces the processing cost but also simplifies the manufacturing process.

The flatness of AS2 is a result of the float glass manufacturing process. When molten glass is floated on a bath of molten tin, it spreads out evenly to form a flat surface. This inherent flatness makes AS2 an excellent choice for applications where a even glass surface is critical.And, we can provide specially designed glass with good flatness according to customer requests.

High heat& weather resistance

AS2 exhibits superior heat and weather resistance when compared to resin products. This makes it suitable for applications that require durability under extreme environmental conditions. This property is particularly important in applications where glass may be exposed to direct sunlight or extreme temperature variations.

AS2 exhibits superior heat and weather resistance when compared to resin products. This makes it suitable for applications that require durability under extreme environmental conditions. This property is particularly important in applications where glass may be exposed to direct sunlight or extreme temperature variations.

Weather resistance is another essential quality of AS2. It can endure the effects of humidity, rain, and other weather conditions without losing its integrity. This resistance to environmental factors is particularly crucial in outdoor applications where glass must maintain its quality and performance over time.

High versatility

AS2's high versatility makes it suitable for a wide range of applications, and it has a proven track record in diverse industries. Its adaptability and reliability make it a superior choice for businesses looking for a high-quality soda-lime glass to meet their unique needs.

AS2's high versatility makes it suitable for a wide range of applications, and it has a proven track record in diverse industries. Its adaptability and reliability make it a superior choice for businesses looking for a high-quality soda-lime glass to meet their unique needs.

Major Applications of AS2

AS2's exceptional characteristics make it a preferred choice in various industries. Here are some of the major applications where AS2 excels:

TN/STN LCD Panels

AS2 is ideal for TN (Twisted Nematic) and STN (Super Twisted Nematic) LCD panels due to its high flatness.

AS2 is ideal for TN (Twisted Nematic) and STN (Super Twisted Nematic) LCD panels due to its high flatness.

LCD technology relies on the precise alignment of liquid crystals sandwiched between two sheets of glass. Any irregularities in the glass can cause color variations in the displayed images. AS2's exceptional flatness ensures that the gap between the glass sheets remains consistent, resulting in uniform colors in the LCD panels.

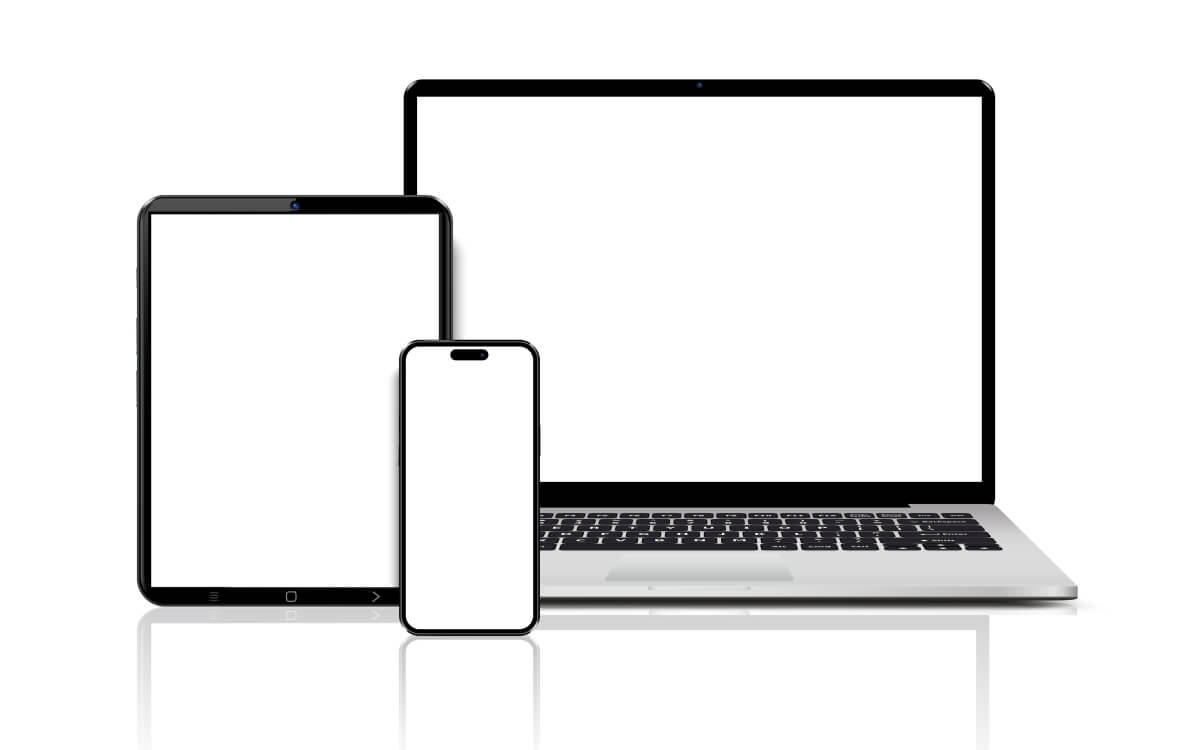

Touch panel/cover glass for electronic devices

AS2's high heat and weather resistance make it suitable for use in touch panels and cover glass for electronic devices. Additionally, AS2 can undergo a higher strength chemical strengthening than traditional soda-lime glass, making it suitable for applications where durability is required.

AS2's high heat and weather resistance make it suitable for use in touch panels and cover glass for electronic devices. Additionally, AS2 can undergo a higher strength chemical strengthening than traditional soda-lime glass, making it suitable for applications where durability is required.

In electronic devices such as smartphones and tablets, the cover glass must withstand the rigors of daily use. AS2's ability to resist heat and environmental factors ensures that these devices remain functional and visually appealing. Additionally, the option for chemical strengthening provides an extra layer of durability, making AS2 an excellent choice for touch panels and cover glass.

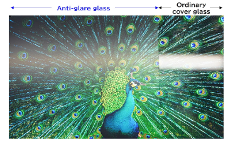

AGC’s Related Product

Anti-Glare Etched Glass

AGC's Anti-Glare Etched Glass is an innovative solution designed to mitigate the issue of glare on display panels, enhancing visibility and functionality.

Mirror substrates

AS2 is used in mirror applications in electronics, automotive, and head-up displays. Its high flatness and optical quality ensure high-definition images, making it ideal for mirror substrates where clarity is paramount.

AS2 is used in mirror applications in electronics, automotive, and head-up displays. Its high flatness and optical quality ensure high-definition images, making it ideal for mirror substrates where clarity is paramount.

Mirrors are not just for personal grooming; they have extensive applications in various industries. In the automotive sector, for example, head-up displays rely on high-quality mirror substrates to project essential information onto the windshield. AS2's flatness and optical properties ensure the displayed information is clear and accurate, contributing to driver safety and convenience.

AGC’s Related Product

Automotive Display Glass

Automotive Display Glass is becoming larger, more complex, and more functional every year. The elements required of glass are "low reflectivity," "safety," and "antifouling". This article introduces three technologies to meet these requirements.

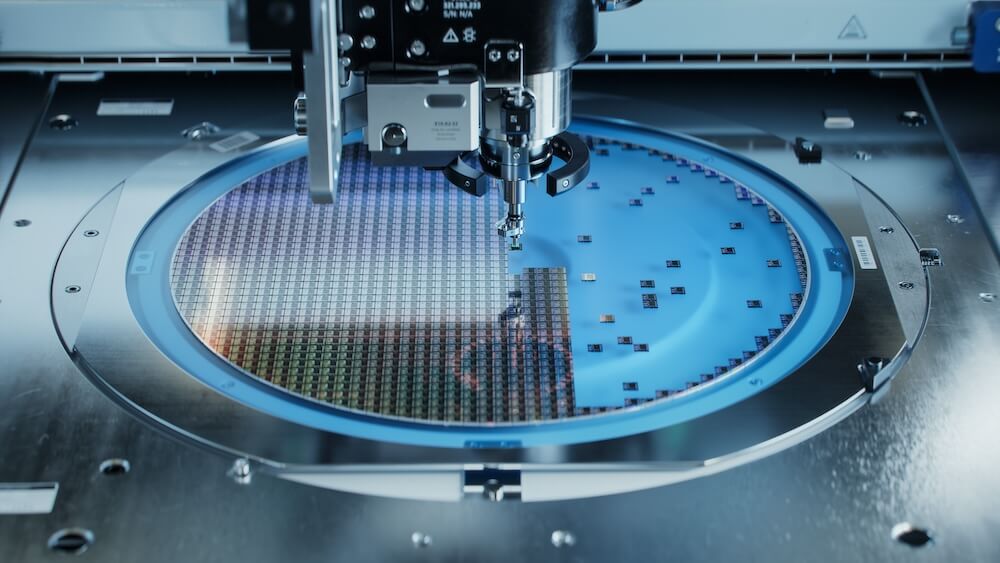

Carrier substrates for electronic components

Thanks to its high flatness, heat resistance, and chemical resistance, AGC's soda-lime glass is often used as carrier substrates for electronic components. These substrates provide a stable and reliable platform for electronic devices to be built upon.

Thanks to its high flatness, heat resistance, and chemical resistance, AGC's soda-lime glass is often used as carrier substrates for electronic components. These substrates provide a stable and reliable platform for electronic devices to be built upon.

Electronic components, from microchips to sensors, require a stable platform for mounting and connecting. AGC's soda-lime glass's properties ensure that electronic components are secure and functional, even in challenging conditions. Its ability to maintain its flatness and withstand temperature fluctuations is vital in maintaining the integrity of electronic systems.

02/What is Soda lime float glass?

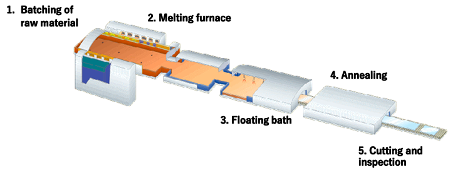

Soda lime float glass is a high-quality glass made through a unique manufacturing process. AGC's Soda lime float glass is a result of their expertise and innovation. It is created by floating molten glass on a molten metal’s bed, usually tin, which allows the glass to spread out into a flat sheet. This process is highly efficient and results in glass with uniform thickness and flatness. AGC's Soda lime float glass, including the AS2 product, offers a wide range of advantages, making it ideal for various applications.

Soda lime float glass is the foundation of many products we use daily, including windows, mirrors, and glass screens. It's created by heating raw materials like silica sand, soda ash, and limestone until they melt into molten glass. This molten glass is then carefully poured onto a bath of molten tin, which is even flatter than water. The glass spreads out, forming a smooth and perfectly flat surface. As it cools and hardens, the glass retains this flatness, making it highly desirable for a wide range of applications.

03/FAQs about AS2

Here are some common questions about AS2:

-

What distinguishes your float glass as "High-Quality"?

-

The distinctive features of AS2, as mentioned above, are achieved through the float glass production process. AGC's commitment to precision and quality control ensures that AS2 meets the high standards in terms of wide range of thickness and flatness. These attributes set it apart as a high-quality float glass product.

-

What are the available thickness options and dimensions for your float glass?

-

AS2 offers a wide range of thickness options, ranging from an ultra-thin 0.23mm to a sturdy 6mm. This diversity in thickness allows AS2 to cater to various application.

For even thinner plate thicknesses, AGC is open to consultation, and they can explore plate thicknesses of 0.2mm or even less. This flexibility enables AGC to provide tailored solutions to meet the specific requirements of their customers.

Specific dimension information can be provided by contacting AGC directly. AGC recognizes that applications may vary widely in size and shape, and they are equipped to provide guidance and customization based on individual project needs. -

Do you offer any coatings or treatments, such as anti-reflective or chemical strengthening options?

-

AGC takes a customer-centric approach when it comes to coatings and treatments. They can accommodate various coating and treatment requests based on specific conditions and requirements.

Whether you need an anti-reflective coating to enhance visibility or tempered glass for added strength and safety, AGC will work with you to provide the desired solution. It is advisable to contact AGC with your specific needs to discuss the possibilities in detail. -

How can I get more detailed information about AS2?

-

For detailed information about AS2, please make a request through the inquiry form on the AGC specialty glass website. Depending on your application, we can send you information such as datasheets.

Contact us!

AGC is committed to providing excellent customer service and addressing any inquiries or orders promptly.

To get in touch with AGC, you can visit their speciality glass website and use the contact form providede.Their dedicated team will assist you with your specific requirements and guide you through the process.

AGC's committment to innovation and customer satisfaction ensures that the float glass products remain a preferred choice across industries worldwide. When it comes to AGC's AS2, you're not just getting glass; you're getting a high-quality, tailor-made solution to enhance your products and applications. Whether it's for advanced electronics, mobility, or any other industry, AGC's AS2 has the features and flexibility to meet the demands of today's diverse and ever-evolving world.