AGC Thin Glass Solutions

- Choose from a wide range of thin glass products

- Supporting The Development Of Glass Suited To Customer Needs

- High-quality Glass Processing

- Chemical Strengthening

- Cutting for Wafers and Panels and Edge Processing

- Polished Surface Processing

- Ultra-Thin Glass Processing

- Surface Treatments (AG/AR)

- Automotive Displays

- Solar panel cover glass

- Carrier glass used in manufacturing processes

- Other Applications

- EG-S1

- Carrier Glass Technology with Bonding Layer

- Inquiries

- Understanding Our Customers

- Sample Work Pieces

- Evaluation and Feedback

- Adoption

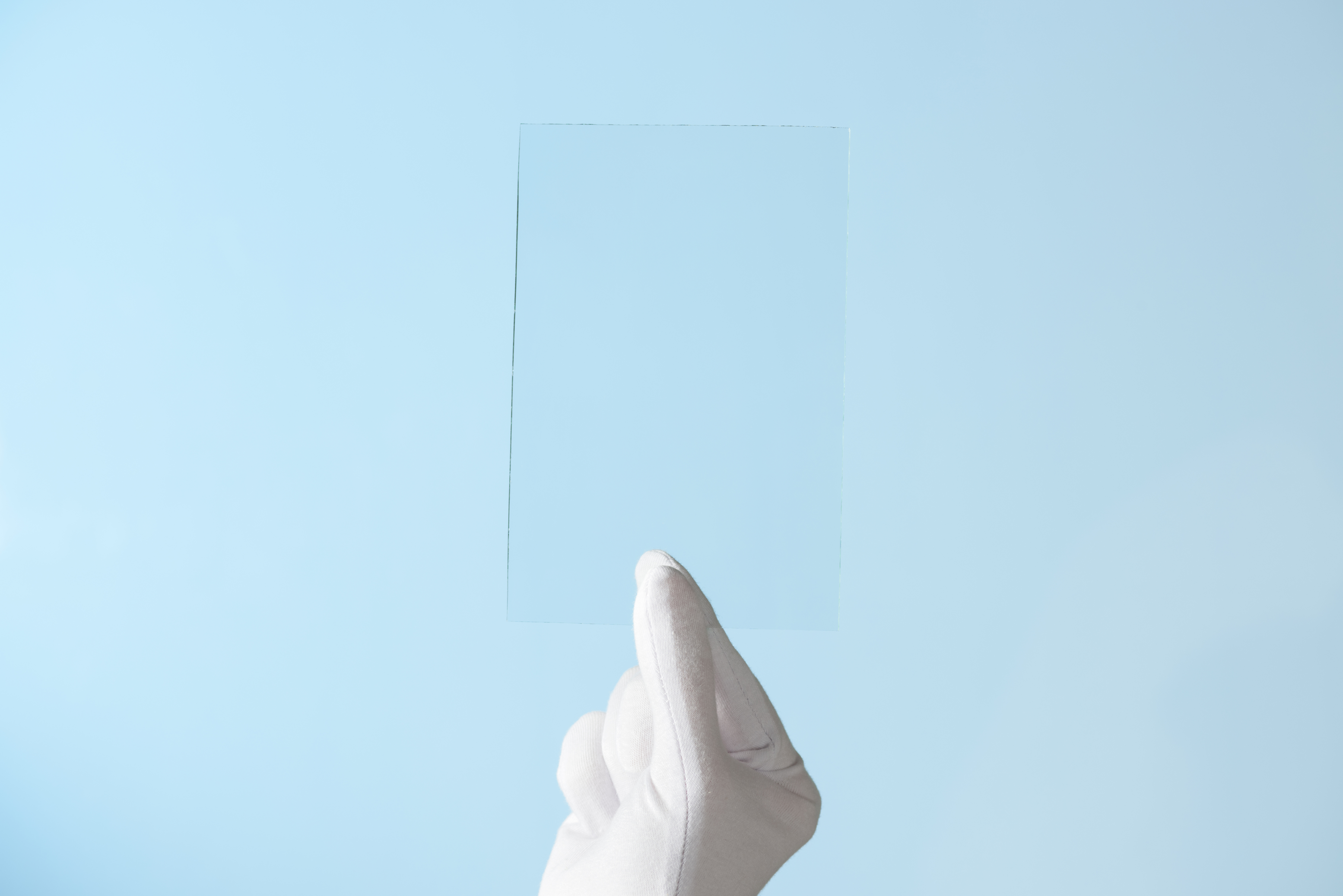

01/AGC's Thin Glass Solutions

AGC is a leader in specialty glass solutions, offering high-performance thin glass materials tailored to various industries. AGC’s thin glass solutions combine a wide selection of glass materials, glass development based on customer needs, and advanced glass processing technologies to customize and provide optimal specialty glass products through a one-stop service.

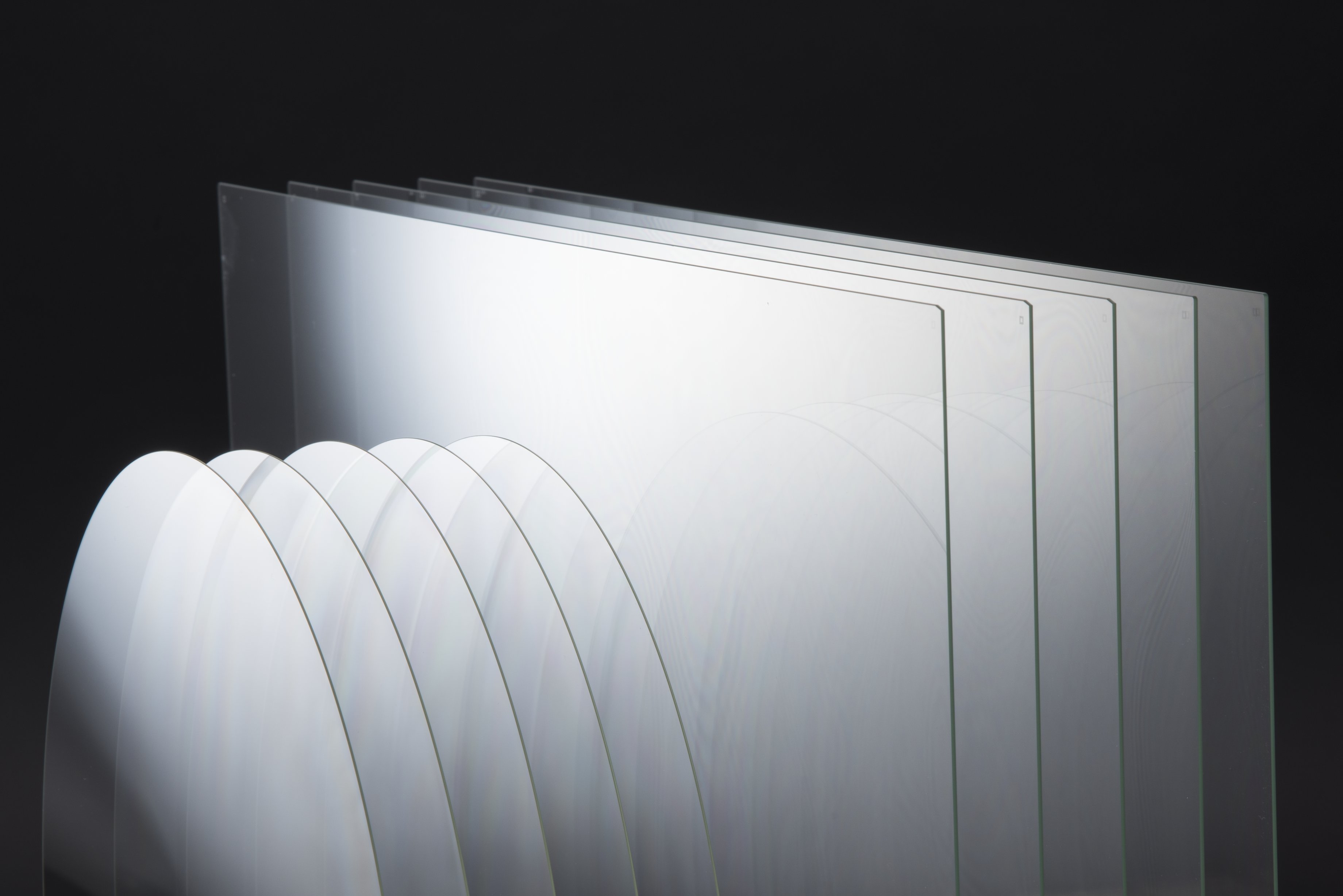

Choose from a wide range of thin glass products

AGC offers a variety of glass materials in different thicknesses, sizes, and properties such as transmittance, CTE (coefficient of thermal expansion), and Young’s modulus. Glass thickness options range from 0.23 to 6 mm, and we can also accommodate ultra-thin glass below 0.2 mm upon request, making them suitable for many applications. From chemically strengthened glass for electronic devices and in-vehicle displays to glass for solar panels and carrier glass used in manufacturing processes, AGC provides materials based on customer needs and product requirements.

Supporting The Development Of Glass Suited To Customer Needs

If standard glass products don’t meet specific requirements, AGC works with customers to create custom solutions. By putting its focus on research and development, AGC continues to improve existing glass and develop new types. We are able to develop and improve new types of glass to meet a variety of customer needs, such as enhanced durability, optical transparency, and chemical resistance.

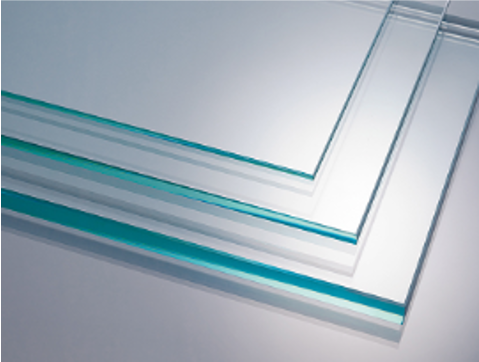

High-quality Glass Processing

AGC processes high-performance glass, including aluminosilicate and soda-lime glass, in a range of sizes and features. Glass can be customized to specific thicknesses, shapes, and surface finishes. To meet the needs of various industries that demand precision and reliability, we listen to your desired specifications and provide processed glass through a one-stop solution.

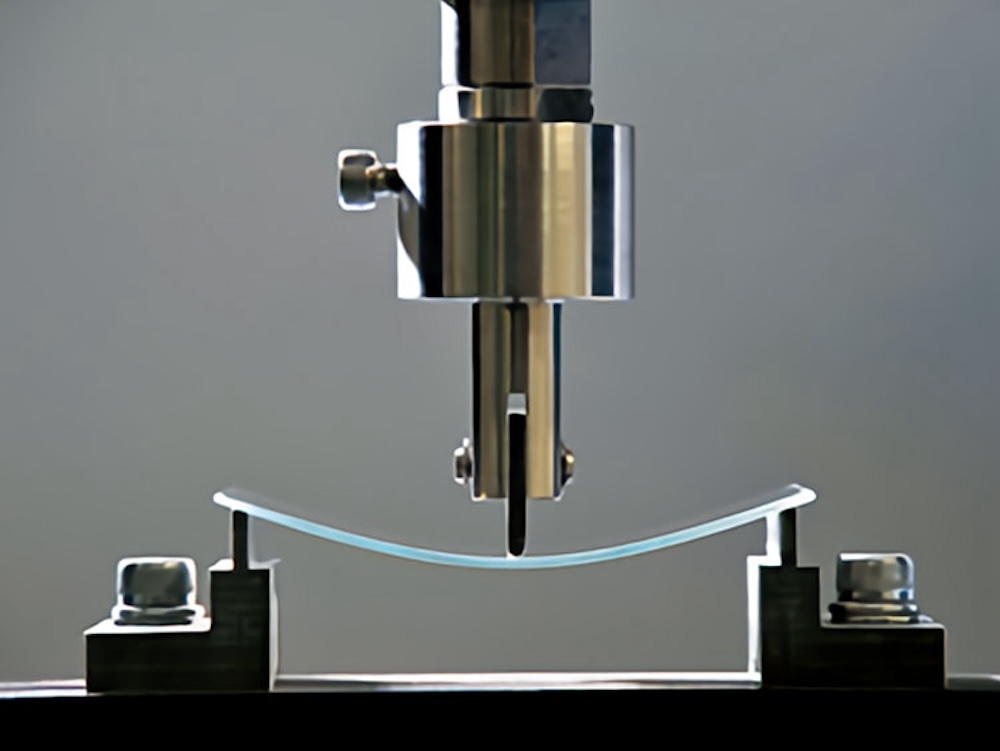

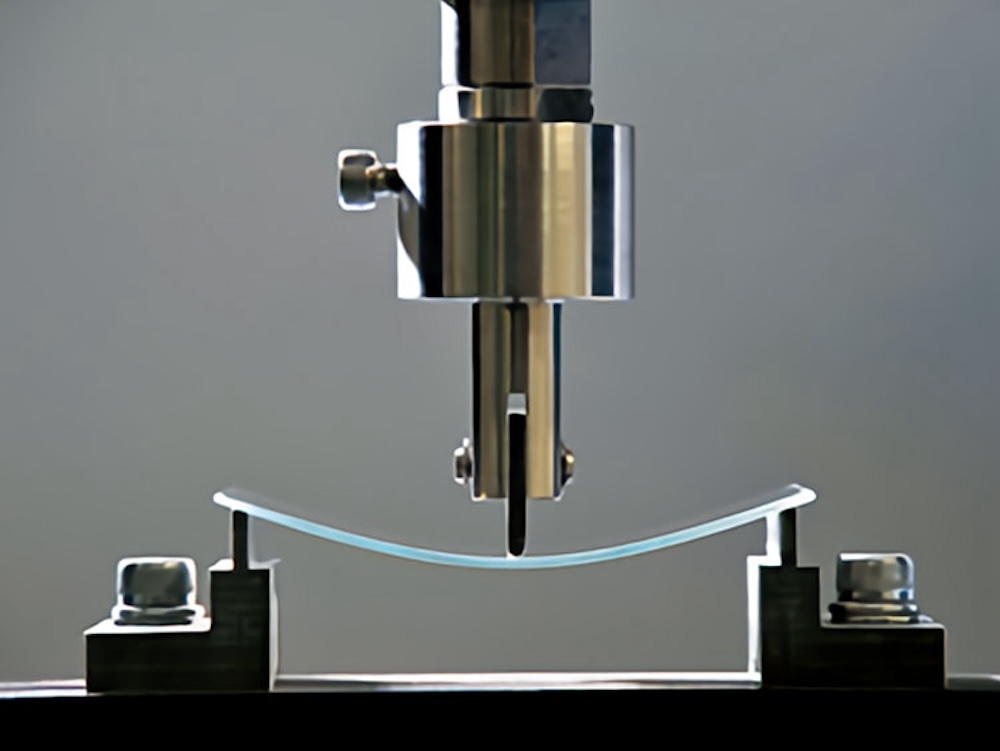

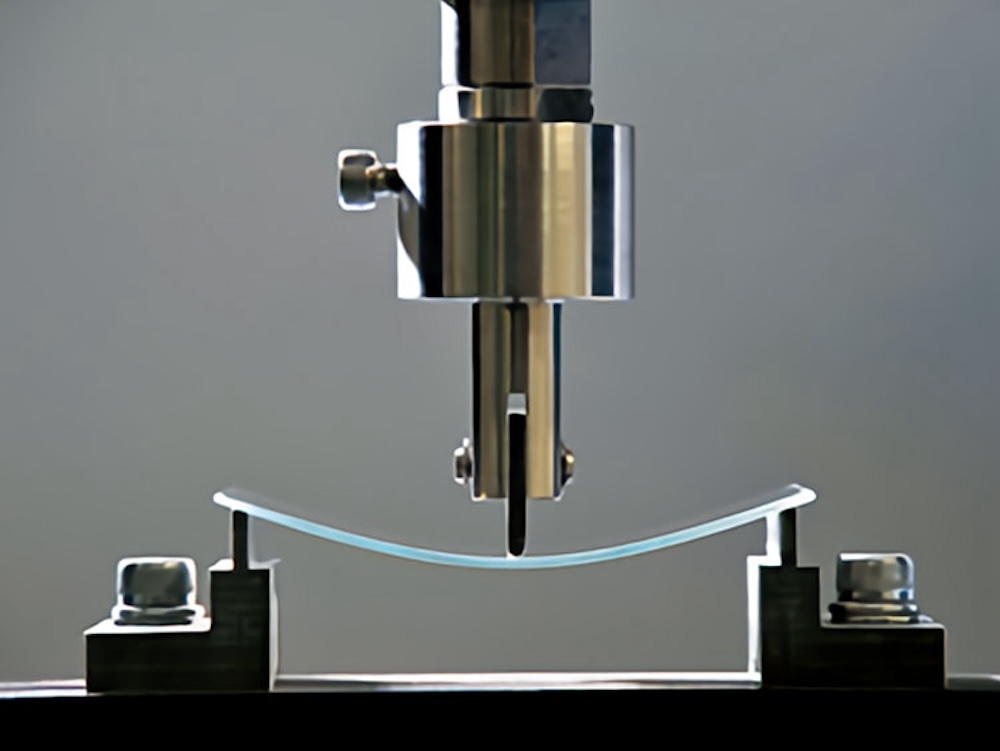

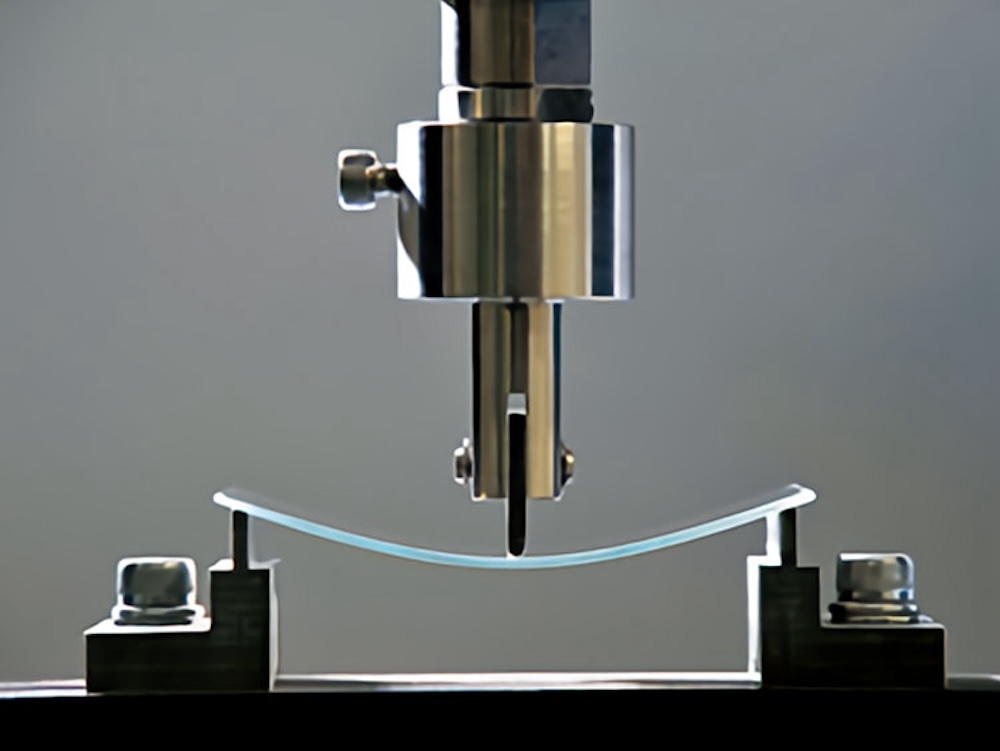

Chemical Strengthening

Chemical strengthening is a specialized process that increases the strength, durability, and scratch resistance of glass. During this process, the glass is immersed in a heated potassium salt bath, allowing larger potassium ions to replace smaller sodium ions on the glass surface. This ion exchange creates compressive stress, which improves the glass’s ability to withstand mechanical impacts and resist bending.

This approach is ideal for cover applications where glass is frequently used or needs to withstand environmental stress, such as in smartphones, automotive displays, cameras, and sensors.

AGC’s chemical strengthening process can be customized based on the glass type and intended use, ensuring the best performance for each product.

Cutting for Wafers and Panels and Edge Processing

AGC provides cutting and edge processing in sizes and tolerances tailored to customer needs. We can process glass into the desired shapes, whether it's glass wafers, panel substrates, or complex, irregularly shaped substrates, and deliver them through a one-stop solution. For edge processing—an important step in enhancing the safety, durability, and handling of glass—we offer a variety of edge finishes such as rounded, chamfered, and polished edges, all customizable to meet specific performance and design requirements.

Polished Surface Processing

Polished surface processing enhances the glass’s smoothness and clarity. This process removes microscopic imperfections and surface roughness, resulting in a flawless finish that improves both visual and functional performance.

Precisely polished glass is used in applications such as in-process carrier substrates, MEMS, and bio-devices.

At AGC, we accommodate a wide range of specifications by customizing according to customer requirements for size, thickness, TTV (Total Thickness Variation), surface roughness, and more.

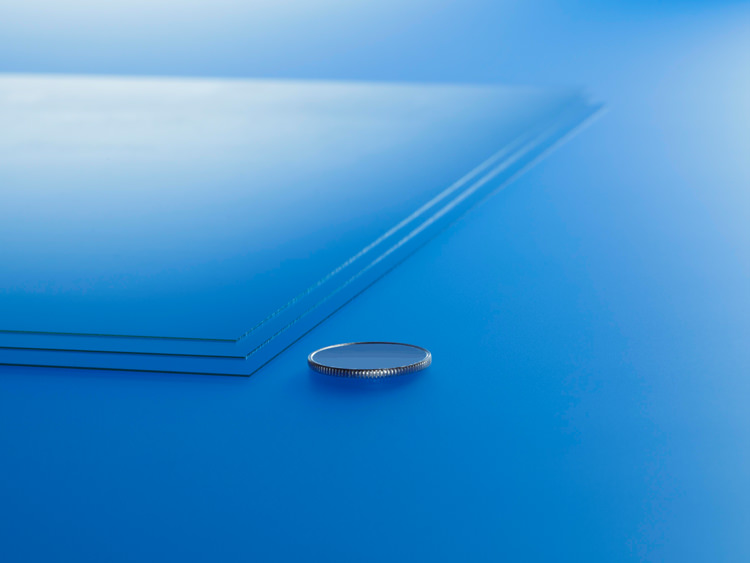

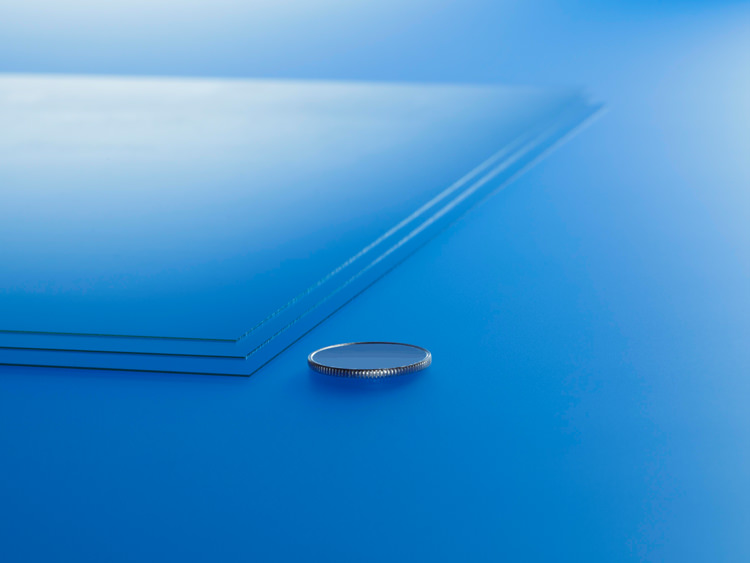

Ultra-Thin Glass Processing

AGC can provide glass with a thickness of 0.2 mm or less based on customer requirements.

Ultra-thin glass is essential for next-generation devices that require lightweight, durable materials without compromising performance.

This type of glass is used in a variety of advanced applications:

• Foldable Devices: Ultra-thin glass is flexible enough to be used in foldable smartphones, tablets, and other portable electronics.

• Wearable Technology: Its lightweight and durable properties make it ideal for smartwatches and fitness trackers.

Our expertise in ultra-thin glass processing allows us to deliver custom solutions that meet the most demanding technical and design challenges.

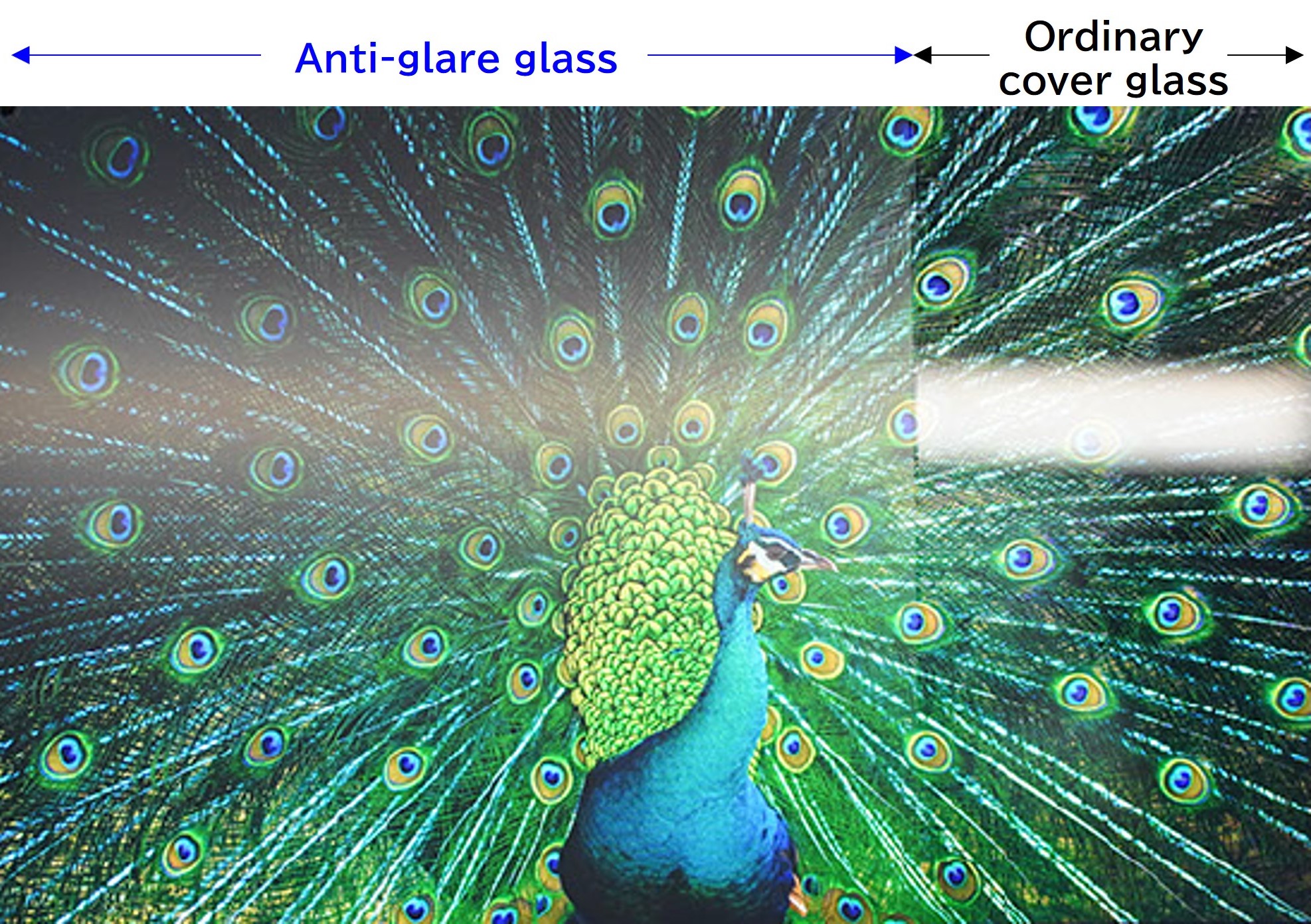

Surface Treatments (AG/AR)

AGC offers advanced surface treatments to enhance the optical performance and functionality of its glass. These treatments are particularly useful for improving visibility in challenging environments.

Anti-glare (AG) treatment reduces surface reflections by scattering incoming light. It is ideal for devices used in bright or outdoor settings, as it minimizes glare and improves screen readability. Anti-glare treatment is commonly applied to automotive displays, public information kiosks, and medical monitors.

Anti-reflective (AR) treatment reduces the amount of light reflected from the glass surface, allowing more light to pass through. This results in improved image clarity and reduced reflections, which is particularly important for optical devices, high-resolution displays, and scientific instruments.

Both treatments can be combined with other processing techniques to deliver glass that meets the highest standards of visual clarity and performance.

Anti-glare glass

Ordinary cover glass

02/Applications of AGC’s Thin Glass

AGC’s thin glass is used across a wide range of industries to improve performance, durability, and user experience. Its advanced processing technologies ensure that each product meets the highest standards for quality and reliability.

Automotive Displays

Modern vehicles rely on advanced digital displays for navigation, entertainment, and safety information. AGC’s glass is engineered to provide clear visibility, resist extreme temperatures, and maintain performance in demanding automotive environments.

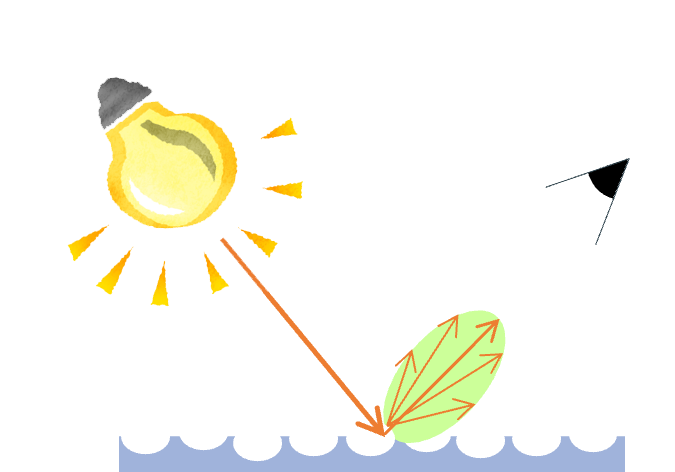

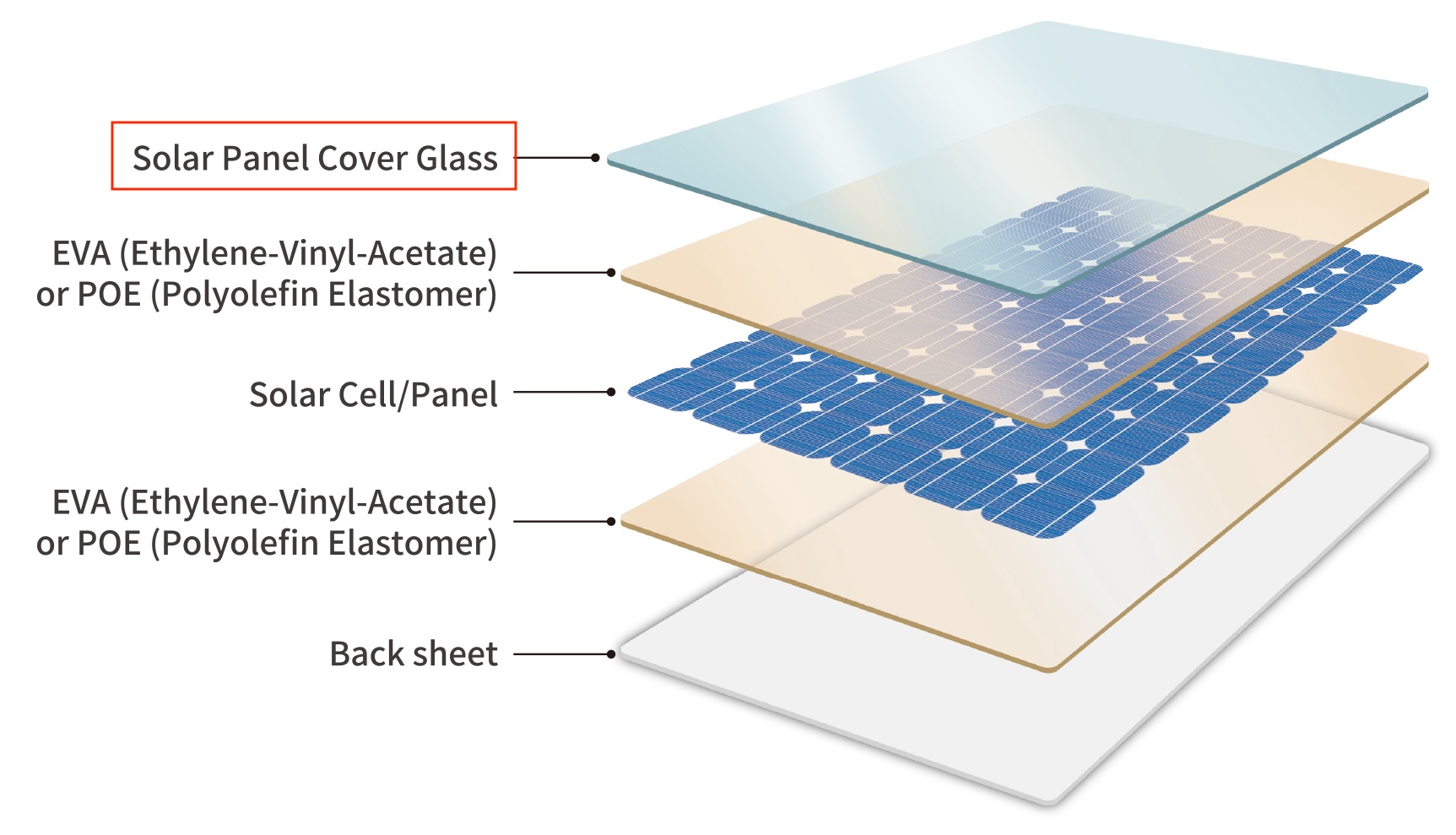

Solar panel cover glass

AGC’s thin glass plays a vital role in improving for both terrestrial and space-based solar panels efficiency. Its high transparency allows maximum light absorption, while its durability protects against weather conditions. This combination extends the lifespan of solar panels while improving energy output. The use of thin glass also contributes to the weight reduction of solar modules.

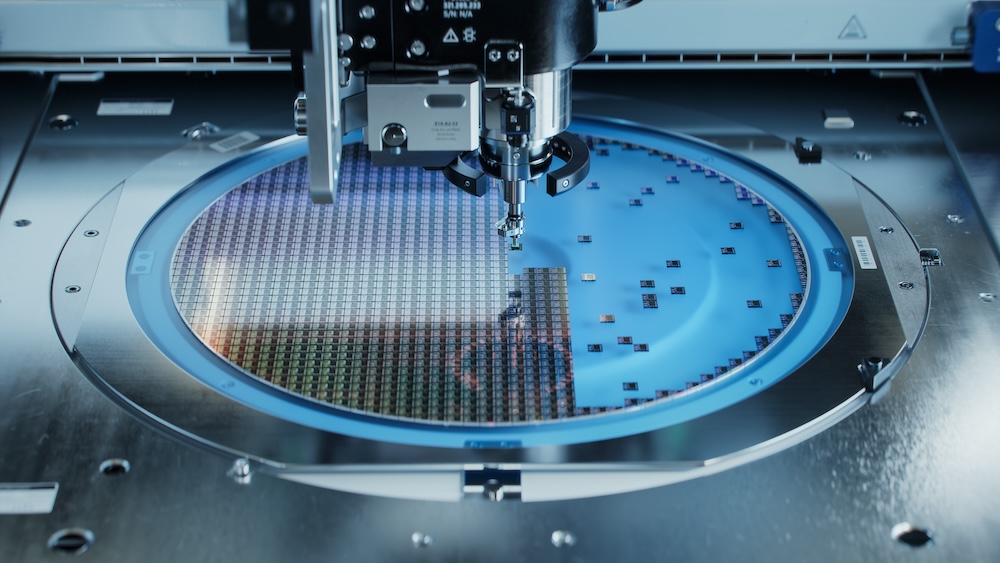

Carrier glass used in manufacturing processes

We provide glass for use as carrier substrates in the manufacturing processes of sensors and electronic devices. By understanding requirements such as size, thickness, CTE, and TTV, we deliver glass substrates that match your process through a one-stop solution.

Other Applications

We work closely with customers to develop custom solutions that meet specific technical and operational needs.

By combining advanced glass processing technologies with a commitment to quality and innovation, we deliver solutions that support today’s most advanced and demanding industries.

03/AGC’s Specialty Glass Products

AGC offers several specialized glass products, each designed for specific uses:

EG-S1

AGC's Satellite Solar Cell Cover Glass, EG-S1 protects satellite solar panels from harsh space conditions with UV shielding and electron beam resistance. It prevents discoloration from radiation, maintaining solar cell efficiency. Customizable in thickness and shape— Approximately 0.1 mm—EG-S1 suits various satellite projects, including solar cells and optical solar reflectors.

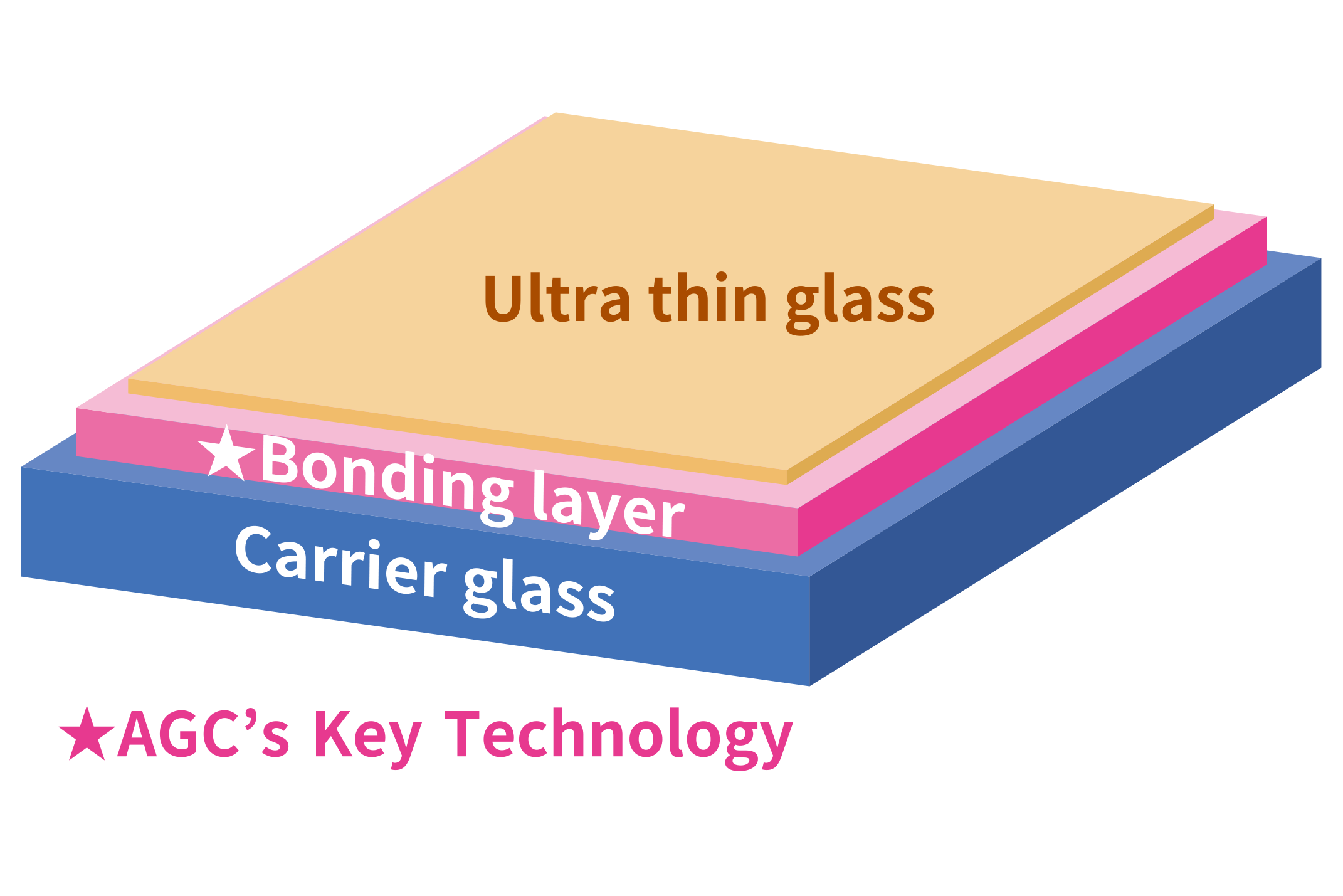

Learn moreCarrier Glass Technology with Bonding Layer

A special adhesive layer is used to bond ultra-thin glass (UTG) to a more durable carrier glass, making it easier to handle during manufacturing. AGC's special adhesive layer enables the separation of ultra-thin glass from the carrier glass through a mechanical process called Mechanical Lift-Off (MLO).With heat resistance up to 400°C and large size options, it’s ideal for flexible sensors, wearable tech, and thin devices. Contact AGC to learn more.

Learn more04/Workflow After Inquiries

At AGC, we combine specialty thin glass with a wide range of processing technologies to provide the glass products our customers need through a one-stop solution. With our collaborative approach, we deliver customized solutions that meet performance requirements across industries such as electronics, life sciences, and automotive.

-

Inquiries

-

Understanding our customers

-

Sample work pieces

-

Evaluation and feedback

-

Adoption

1Inquiries

We welcome inquiries from various industries and thoroughly review each project’s specific requirements. Our team works to understand the technical challenges and desired outcomes, ensuring we deliver the most effective glass solutions.

2Understanding Our Customers

We engage with clients through in-depth discussions to understand their unique needs, performance expectations, and application environments. This collaborative approach allows us to propose tailored solutions that align with both technical and business goals.

3Sample Work Pieces

We provide sample work pieces that reflect the requested specifications. These samples allow clients to test and evaluate our materials under real-world conditions, ensuring they meet required performance standards before moving to full-scale production.

4Evaluation and Feedback

Clients assess the sample pieces and provide detailed feedback. We use this input to refine our processes and adjust material properties if needed. This iterative approach ensures that our glass solutions meet or exceed performance expectations.

5Adoption

Once the solution is approved, we move to full-scale production, delivering consistent, high-quality glass products tailored to the client’s specifications. Our flexible manufacturing processes allow us to accommodate diverse design needs and performance requirements across industries.

05/Contact AGC

AGC’s team of experts is available to assist with custom thin glass solutions for a wide range of industries and applications. For specialized glass materials, advanced processing solutions, or expert technical support, contact us today to explore how AGC can support your project.